Digital Twins Product Development: The Future of SaaS

- May 29, 2023

-

3170 Views

- by Ishan Vyas

Table of Contents

- Digital Twin Product Development

- What is Digital Twin Technology?

- How do Digital Twins work?

- When to use Digital Twin Technology?

- Types of Digital Twins

- Digital Twins v/s Simulation

- How will Digital Twin Technology affect Product Development?

- Applications of Digital Twins in various Industries

- Benefits of using Digital Twins for Product Development

- What is the Future of Digital Twin Technology?

- Citrusbug – One-stop solution for your Digital twins’ Product Development

- Conclusion:

Digital Twin Product Development

The curiosity of this generation is pushing boundaries to understand trending technologies. You must also be curious about this new technology called a digital twin. The technology is still breaking new ground in the area of product development, including digital twin solutions. This groundbreaking new concept allows businesses to create a virtual replica of physical products or systems.

Furthermore, it opens up new monitoring, analysis, and innovation possibilities. In 2025, it is expected that there will be a $6 million USD market for digital twin technologies. Following the title of our blog, we will unlock things regarding digital twins that show digital transformation.

What is Digital Twin Technology?

Digital twin technology refers to the creation of a virtual mirror image of any physical product or system. It captures real-time data and provides a digital representation that imitates the behavior, structure, and characteristics of the product. By combining sensors, the Internet of Things (IoT), and development analytics, the digital twin offers a powerful tool for product development, fostering extensive monitoring, analysis, and simulation.

From millimeters to kilometers in size, digital twins can accurately represent a wide range of real-world objects. In other words, you can digitally duplicate anything, from a small thing like a human organ to a large entity like an entire city.

How do Digital Twins work?

For development, software engineers extract data from various sources. The collected data is centrally stored in the cloud. A virtual imitation of the assets is used to evaluate and simulate the data. Combining historical data, sensors, and IoT devices, digital twins are generated with integrated data. After receiving the information from the simulation, the parameters are applied to real assets. This process of data exchange keeps the digital twin and physical counterpart in sync and provides real-time insights into their performance, health, and behavior. These insights can be leveraged to optimize operations, predict maintenance needs, conduct simulations, and facilitate informed decision-making.

Therefore, digital twins are a real-time investment if you want to make a financial commitment to technology. Leverage digital twins for valuable business outcomes in the digital world.

When to use Digital Twin Technology?

According to an analysis of the demand for digital technologies, the use of digital twins is beneficial for the mentioned requirements.

- Complex systems or product life cycles require continuous monitoring and analysis.

- Predictive maintenance is crucial to minimizing downtime and optimizing performance.

- Simulation and testing are required to assess product behavior under different conditions.

- Rapid prototyping and iteration are essential for efficient development and improve performance.

- Data-driven decision-making is preferred over traditional trial-and-error approaches..

- For better reach you can generate a QR code with free tools like Uniqode and increase the engagement of the product.

The points mentioned above span a wide range of applications, including planning, product development, logistics, quality control, production, etc. The digital twin approach indeed delivers a quality production process and increases business value.

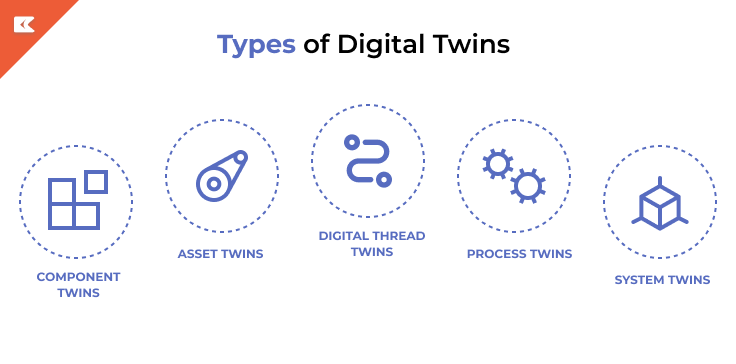

Types of Digital Twins

Digital twins can be classified into several categories based on their applications and focus. Some common types of digital twins include:

- Component Twins

- Asset Twins

- System Twins

- Process Twins

- Digital Thread Twins

Component Twins:

Component twins are a digital simulation of a real-world individual item, like a screw or gear. These replicas focus on capturing and simulating the behavior and performance of individual products.

Asset Twins:

Asset twins can also be referred to as product twins. However, the difference between component and asset twins is that asset twins focus on the whole physical product rather than particular items. Also, we can consider that the asset twins concentrate on the cluster of component twins. Furthermore, asset twins monitor and optimize the performance of specific assets or equipment.

System Twins:

You can observe how different assets function together at this level of a digital twin, providing you with an up-close look at how they interact and where improvements may be made. System twins encompass complex systems, such as industrial plants or smart infrastructure, and enable comprehensive monitoring and control.

Process Twins:

The process twins demonstrate how every unit works together in the entire production plant and how the process can be streamlined. In addition, it simulates and analyzes manufacturing operations to enhance efficiency.

Digital Thread Twins:

Digital thread twins provide end-to-end visibility across the product lifecycle, integrating data from various stages and stakeholders.

Digital Twins v/s Simulation

While digital twin technology and simulation are nearly connected, they vary in scope and purpose. The simulation focuses on anticipating product behavior based on mathematical models, while digital twins leverage real-time data to provide a more accurate virtual representation of the physical counterpart. Digital twins offer dynamic insights into real-world conditions, allowing for continuous monitoring, optimization, and simulation based on actual operational data.

In addition, product developers leverage this technology for some functions pointed out below:

- Estimate prototype or product design

- See how a product or process reacts under certain conditions

- Create a product before physically building it

- Plan and monitor product life cycles

This technology always focuses on delivering a visionary result that helps businesses understand the importance of following the right Digital Product Development Process. By creating a virtual replica of a physical product, digital twins provide valuable insights throughout every stage of the development lifecycle, ultimately leading to better products and faster time-to-market.

How will Digital Twin Technology affect Product Development?

For product development, this technology includes several key benefits.

1. Enhanced Performance:

Real-time monitoring and analysis help companies locate performance bottlenecks, streamline processes, and raise production efficiency all around.

2. Proactive Maintenance:

Digital twins can forecast maintenance requirements, cut downtime, and take preventive measures to address problems by tracking the health and behavior of items or systems.

3. Streamline Development Process:

Digital twins aid in quick prototyping, iterative design, and virtual testing, which lead to a quick product development cycle and a shorter time to market.

4. Data-driven decision-making:

A more effective and efficient approach is made possible by accurate, real-time data from digital twins, which helps organizations make wise judgments.

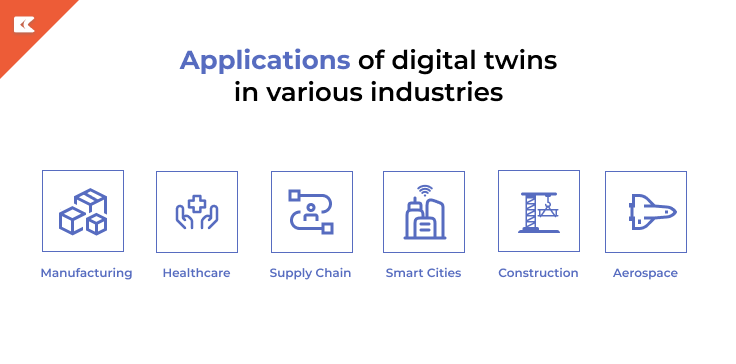

Applications of Digital Twins in various Industries

Digital twins are the most adaptable tool for many industries. It gives a technical touch to assist businesses in providing flawless processes for systems and enhancing the performance of the product life cycle. There are countless chances it offers, and the results are evident. Let’s identify the industries that are utilizing digital twin services at the forefront.

Let’s find applications in a wide range of industries, including:

- Manufacturing

- Healthcare

- Supply chain

- Smart cities

- Construction

- Aerospace

Manufacturing:

The digital twin is a boon to the manufacturing industry. Building a virtual product before starting the manufacturing process results in a clear vision and an understanding of how the product is made.

In the manufacturing industry, this technology offers optimized production lines, prediction of equipment failure, and prediction of maintenance.

Healthcare:

A digital twin is an excellent innovation that will revolutionize the healthcare sector. Imagine being able to create a digital patient model that contains data from medical equipment that is being used in real-time. For healthcare professionals, having a virtual replica of the patient’s case will help them study the patient closely.

The main focus of the digital twin in the healthcare industry is to simulate patient health and treatment scenarios, enhance medical device development, and support telemedicine.

Supply Chain:

The use of digital twin solutions is revolutionizing the logistics and transportation sectors of the supply chain, enabling organizations to reduce costs by streamlining their operations.

For instance, a business can monitor its performance in real-time using information from IoT sensors and other sources by developing a digital duplicate of its logistics and transportation systems. Proactive measures can be taken to prevent expensive downtime if delays or bottlenecks are identified.

Smart cities:

The development of digital twin technology has enormous potential as a tool for city administrators and planners. They may better understand how everything works. Furthermore, analyzing the changes can be done by building virtual representations of a city’s resources, services, and infrastructure.

The main purpose of this technology in smart cities is to simulate and manage infrastructure systems, optimize energy consumption, and improve urban planning.

Construction:

Construction project design, planning, and execution are all visible in exceptional detail thanks to this technology. The virtual imitation of the design assists the professional to streamline project management, improve safety and quality control, and enhance building lifecycle management.

Aerospace:

Businesses in the aerospace sector have many options thanks to the digital twin concept, from prolonging the life of components and equipment to using data to enhance the next iteration of them. The digital twin technology serves to monitor aircraft performance, optimize maintenance schedules, and provide virtual testing and simulation.

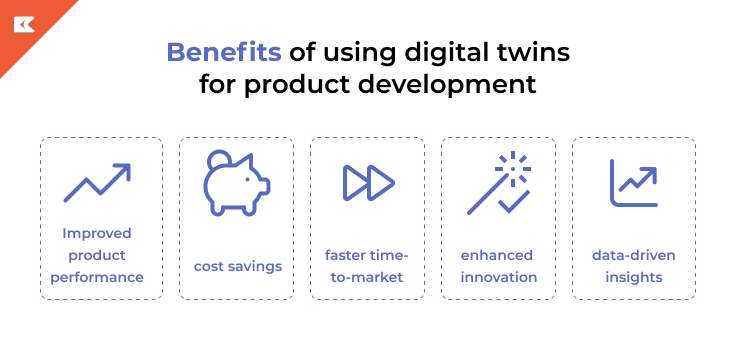

Benefits of using Digital Twins for Product Development

The adoption of digital twins in product development offers numerous benefits, including:

- Improved Product Performance:

Real-time monitoring and analysis enable proactive optimization and continuous improvement.

- Cost Savings:

Predictive maintenance, reduced downtime, and optimized operations result in significant cost savings over the product lifecycle.

- Faster time-to-market:

Rapid prototyping, virtual testing, and streamlined iterations expedite the product development process.

- Enhanced Innovation:

Digital twins provide a platform for experimentation, simulation, and optimization, fostering innovation and creative problem-solving.

- Data-driven insights:

Accurate, real-time data empowers data-driven decision-making, facilitating strategic planning and improved product design.

What is the Future of Digital Twin Technology?

The technology of digital twins appears to have a bright future. The amount of data available for digital twin models will skyrocket as IoT devices and sensors spread like wildfire. Artificial intelligence and machine learning developments will make it possible to create sophisticated simulations, make more precise predictions, and make autonomous decisions based on current information. Digital twin integration will also enable cross-industry collaborations and innovations that go beyond conventional boundaries.

Citrusbug – One-stop solution for your Digital twins’ Product Development

For businesses seeking to harness the potential of digital twins, Citrusbug Technolabs offers comprehensive solutions tailored to specific needs. With expertise in software development, IoT integration, and data analytics, Citrusbug helps businesses create and advantage digital twins to optimize product development, enhance performance, and drive innovation.

Following artificial intelligence and machine learning expertise, enhancing our digital transformation services with digital twin development. We are delighted to offer our services to turn your idea into reality.

Conclusion:

Let’s wrap up here with the answers regarding our topic. Digital twin technology is revolutionizing product development by providing virtual replicas that facilitate real-time monitoring, analysis, and simulation. Its applications span various industries, offering benefits such as performance optimization, predictive maintenance, streamlined development processes, and data-driven decision-making. As the future of digital twin technology unfolds, businesses stand to unlock new levels of innovation, efficiency, and competitiveness. Future business processes are awaiting and welcoming such innovations.

If you are looking for a reliable partner for digital twin product development, Citrusbug Technolabs is a leading Digital Product Development Company that specializes in software development, IoT integration, and data analytics. Our commitment to innovation and expertise in artificial intelligence and machine learning make us the ideal choice for turning your ideas into reality. Let’s embark on a journey of optimization, enhanced performance, and innovation together.

SaaS Development

SaaS Development Web Application Development

Web Application Development Mobile Application Development

Mobile Application Development Custom Software Development

Custom Software Development Cloud Development

Cloud Development DevOps Development

DevOps Development MVP Development

MVP Development Digital Product Development

Digital Product Development Hire Chatbot Developers

Hire Chatbot Developers Hire Python Developers

Hire Python Developers Hire Django Developers

Hire Django Developers Hire ReactJS Developers

Hire ReactJS Developers Hire AngularJS Developers

Hire AngularJS Developers Hire VueJS Developers

Hire VueJS Developers Hire Full Stack Developers

Hire Full Stack Developers Hire Back End Developers

Hire Back End Developers Hire Front End Developers

Hire Front End Developers AI Healthcare Software Development & Consulting

AI Healthcare Software Development & Consulting Healthcare App Development

Healthcare App Development EHR Software Development

EHR Software Development Healthcare AI Chatbot Development

Healthcare AI Chatbot Development Telemedicine App Development Company

Telemedicine App Development Company Medical Billing Software Development

Medical Billing Software Development Fitness App Development

Fitness App Development RPM Software Development

RPM Software Development Medicine Delivery App Development

Medicine Delivery App Development Medical Device Software Development

Medical Device Software Development Patient Engagement Software Solutions

Patient Engagement Software Solutions Mental Health App Development

Mental Health App Development Healthcare IT Consulting

Healthcare IT Consulting Healthcare CRM Software Development

Healthcare CRM Software Development Healthcare IT Managed Services

Healthcare IT Managed Services Healthcare Software Testing services

Healthcare Software Testing services Medical Practice Management Software

Medical Practice Management Software Outsourcing Healthcare IT Services

Outsourcing Healthcare IT Services IoT Solutions for Healthcare

IoT Solutions for Healthcare Medical Image Analysis Software Development Services

Medical Image Analysis Software Development Services Lending Software Development Services

Lending Software Development Services Payment Gateway Software Development

Payment Gateway Software Development Accounting Software Development

Accounting Software Development AI-Driven Banking App Development

AI-Driven Banking App Development Insurance Software Development

Insurance Software Development Finance Software Development

Finance Software Development Loan Management Software Development

Loan Management Software Development Decentralized Finance Development Services

Decentralized Finance Development Services eWallet App Development

eWallet App Development Payment App Development

Payment App Development Money Transfer App Development

Money Transfer App Development Mortgage Software Development

Mortgage Software Development Insurance Fraud Detection Software Development

Insurance Fraud Detection Software Development Wealth Management Software Development

Wealth Management Software Development Cryptocurrency Exchange Platform Development

Cryptocurrency Exchange Platform Development Neobank App Development

Neobank App Development Stock Trading App Development

Stock Trading App Development AML software Development

AML software Development Web3 Wallet Development

Web3 Wallet Development Robo-Advisor App Development

Robo-Advisor App Development Supply Chain Management Software Development

Supply Chain Management Software Development Fleet Management Software Development

Fleet Management Software Development Warehouse Management Software Development

Warehouse Management Software Development LMS Development

LMS Development Education App Development

Education App Development Inventory Management Software Development

Inventory Management Software Development Property Management Software Development

Property Management Software Development Real Estate CRM Software Development

Real Estate CRM Software Development Real Estate Document Management Software

Real Estate Document Management Software Construction App Development

Construction App Development Construction ERP Software Development

Construction ERP Software Development