How Machine Learning Shapes the Future of Inventory Management?

- January 27, 2025

-

3959 Views

- by Ishan Vyas

Table of Contents

Inventory is essential to every retail and online business. This aspect of the trading business has a big influence on revenue, profitability, and future growth.

Managing inventory can be a difficult and complex task. For retailers and e-commerce companies, order confusion, deadstock issues, low inventory levels, and warehouse disorders are frequent issues. Additionally, the human factor could potentially be a cause of problems.

We believe that if you run a retail store or an online store, using machine learning in inventory management is the answer to your problems. We’ll demonstrate how sophisticated machine learning algorithms can improve your inventory management procedures in this post. These days, the retail supply chain uses machine learning to improve demand forecasting accuracy, avoid excess stock, and optimize inventory levels.

Key Challenges of Traditional Inventory Management Systems

Inaccurate Demand Forecasting: Making future demand predictions based only on past sales data frequently leads to serious forecasting errors, which can cause both overstocking and understocking..

Lack of Real-Time Data: Because traditional systems do not incorporate real-time data, they are sluggish to react to abrupt shifts in consumer demand or interruptions in the supply chain.

Ineffective Inventory Management Procedures: Conventional approaches do not allow for inventory optimization due to their lack of dynamic adjustments, which results in a discrepancy between inventory levels and real market demand.

These systems’ inherent inefficiencies have an impact on supply chain efficiency, lower customer satisfaction, increase operating costs, and affect inventory control procedures.

How Machine Learning transforms inventory management?

A subset of artificial intelligence (AI), machine learning has revolutionized inventory management. ML algorithms are capable of analyzing large volumes of data from a wide range of sources, including past sales data, market conditions, customer demand patterns, and even external factors like weather or economic trends, in contrast to traditional systems that are based on set rules.

Machine learning models process and analyze this data to give retailers data-driven insights that maximize inventory control. Over time, these algorithms enhance their predictions, guaranteeing more precise decision-making. The outcome? Retailers can better meet customer demand, reduce excess inventory, and balance stock levels.

Significance of ML in Inventory Management

Accurate Demand Forecasting

To precisely predict consumer demand, machine learning (ML) can examine past sales data, industry trends, and external factors. An eCommerce retailer can use machine learning (ML) to examine historical sales trends, consumer behavior, website traffic, and even external data, such as weather or social media trends.

Businesses can optimize inventory levels, minimize stockouts, and prevent excess inventory by using machine learning algorithms that take these factors into account to produce more accurate demand forecasts.

- Integrates past sales data with outside variables such as events, weather, and economic indicators.

- Identifies demand trends and seasonality using machine learning

- Continuously increases accuracy by using algorithms that learn on their own

Inventory optimization

Businesses can find the ideal inventory levels for various products with the aid of AI & ML algorithms. These algorithms can determine the ideal balance between carrying costs and stockouts by taking into account variables like lead time, seasonality, and cost constraints.

For example, to ensure that they have enough stock to meet customer demand while minimizing excess inventory and related costs, a consumer electronics company can use machine learning (ML) to analyze production cycles, sales forecasts, and historical data. In real-world applications, many service-based and retail businesses enhance these machine-learning insights with platforms like an efficient inventory management tool to maintain accurate parts visibility, streamline inventory tracking, and reduce costly overstock or stockouts.

- connects to RFID and Internet of Things sensors to provide real-time tracking

- Updates inventory counts automatically across several locations

- creates notifications when stock levels are low or there are odd movements.

Supplier Management Integration

Machine learning can help in enhancing risk assessment, performance tracking, and supplier selection.To find the most dependable and economical suppliers, machine learning algorithms can examine supplier data such as pricing, product quality, and delivery schedules. When combined with effective RFP management, businesses can streamline the supplier selection process by ensuring proposals are evaluated based on accurate performance insights.

An automotive manufacturer, for instance, can optimize supplier selection and guarantee a seamless supply chain flow by using machine learning (ML) to analyze supplier performance metrics like on-time delivery rates and defect rates.

- Automatically generates purchase orders according to demand projections and inventory levels.

- Monitors delivery schedules and supplier performance indicators.

- Oversees several suppliers and incorporates their systems.

Real-time Analytics Dashboards

Important inventory metrics and KPIs are instantly accessible through interactive dashboards. Managers can swiftly make well-informed decisions and pinpoint areas for improvement with the aid of these visual interfaces, which provide comprehensive insights into inventory performance.

- Shows the inventory status and important performance indicators in real time.

- Provides views that can be altered to suit various user roles and requirements.

- Makes it possible to drill down for in-depth analysis.

Anomaly Detection

Advanced algorithms track transactions and inventory movements to spot odd trends or possible problems. By identifying questionable activity, the system ensures data accuracy and guards against losses due to theft, damage, or mistakes.

- Detects anomalous changes or inconsistencies in inventory

- Notifies supervisors of possible instances of theft or loss

- Tracks the quality of the data and highlights any possible recording errors

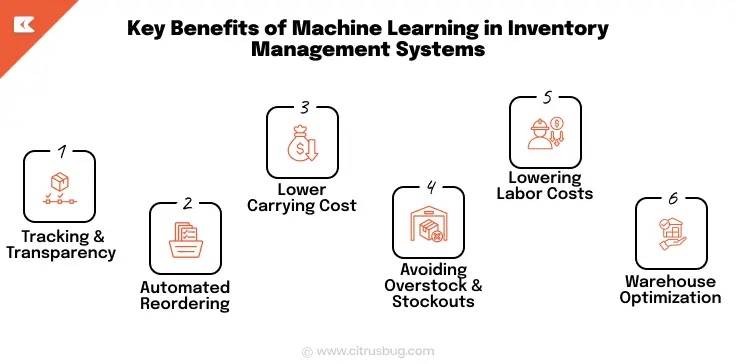

Key Benefits of Machine Learning in Inventory Management Systems

Tracking and Transparency

Time-consuming inventory monitoring could be replaced by an effective supply chain using AI and machine learning in inventory management. Due to human error and a lack of real-time visibility, stock counting and tracking have proven particularly problematic for businesses with inventory dispersed across numerous warehouses, retail locations, and manufacturing facilities.

Costly overselling, understocking, and synchronization problems are frequently the results of this. Automatic product identification, barcode scanning, and stock movement are made possible by advancements in computer vision and sensing.

Automated Reordering

When inventory reaches preset levels, AI-driven systems automatically initiate purchase orders while taking lead times, demand trends, and supplier limitations into account. Human error is decreased, manual procurement procedures are eliminated, and ideal order quantities and timing are guaranteed by this automation.

Lower Carrying Cost

ML systems reduce the cost of storing excess stock by optimizing inventory levels through automated ordering and accurate demand forecasting. The technology lowers warehouse costs and capital committed to inventory by assisting in the maintenance of ideal inventory levels that strike a balance between storage costs and service needs.

Avoiding Overstock and Stockouts

To maintain ideal stock levels, AI algorithms continuously track supply chain variables, sales trends, and inventory levels. By anticipating possible stock outs or excess inventory scenarios before they materialize, the system enables proactive adjustments to avoid lost sales or excessive inventory expenses.

Lowering Labor Costs

The need for manual labor is greatly decreased when routine inventory tasks like ordering, counting, and report generation are automated. AI/ML systems reduce the time and resources required for inventory management while handling repetitive and complex calculations, freeing up staff members to concentrate on strategic tasks.

Warehouse Optimization

Picking tactics, storage locations, and warehouse layouts can all be improved by AI and ML algorithms. Algorithms can recommend the best product placement and picking routes by examining past data and order patterns. This minimizes the time and effort needed for inventory handling in the warehouse.

All things considered, ML in inventory management plays a crucial role in optimizing logistics, increasing the accuracy of demand forecasting, cutting expenses, increasing operational effectiveness, and facilitating proactive decision-making to successfully satisfy customer demands.

Easy Steps to Implementing Machine Learning in Inventory Management

It may seem impossible to implement machine learning into your inventory management procedures, but with the correct knowledge and strategy, it is both possible and very beneficial. The steps to successfully incorporate machine learning into your inventory management system are outlined below:

-

Define Your Goal

Your goals must be well-defined before you can begin machine learning. What do you hope to accomplish with inventory management and machine learning? Having clear objectives in mind is essential, whether the goal is to improve demand forecasting, minimize overstock, avoid stockouts, or optimize supply chains.

-

Assemble and Organize Your Data

Data is necessary for machine learning. A comprehensive dataset comprising past inventory records, demand trends, supplier performance, lead times, and any other pertinent information is required. Your machine learning model is built upon this data.

Make sure the quality of the data comes first. Your machine learning application’s success depends on having clean, accurate, and current data.

-

Choose a Trusted Software Development Partner

Implementing machine learning for inventory optimization isn’t a DIY endeavor. From strategy to deployment, you require a knowledgeable partner with experience in enterprise software development services to help you navigate each step of the process. Here’s what to look for in a partner:

- Seek out a business that has experience developing inventory management software successfully. They ought to be aware of inventory-specific difficulties such as demand forecasting, cycle counting, and safety stock optimization.

- Make sure the partner can create a system that can grow with your company, whether that means adding more SKUs, opening more locations, or integrating with platforms like Shopify and Amazon or retail software development services.

- Avoid one-size-fits-all systems. Custom development will be provided by a reliable partner who will use machine learning consulting services to produce a solution that is specific to your operations.

- To establish a cohesive, data-driven ecosystem, they should guarantee smooth integration with your current systems, including supply chain tools, WMS platforms, and ERPs.

Your ML-based inventory management software will be effective, efficient, and ROI-driven if you choose the right partner.

-

Start with an MVP

Start small with an MVP instead of launching into a full-scale implementation. Utilizing a no-code MVP enables you to quickly test ideas, gather user feedback, and make necessary adjustments without the complexities and costs of traditional development.Concentrate on a particular area, like:

- Demand Forecasting: To make highly accurate predictions about stock requirements, apply machine learning to demand forecasting.

- Reorder Point Automation: To see how ML-driven decision-making increases productivity, automate restocking for high-priority SKUs.

Before implementing your machine learning inventory management system throughout your entire business, MVP development services let you get input, pinpoint areas for improvement, and polish it.

-

Adopt a rigorous testing process and agile development

Agile development is crucial because machine learning changes over time. Develop your system iteratively, taking into account input from practical situations. Testing with both live and historical data guarantees that your system will function dependably after it is put into use.

-

Integration with Your System

It’s time to incorporate your machine learning model into your inventory management system after it has been trained and is operating effectively. Usually, this calls for cooperation between your organization’s domain experts, IT specialists, and data scientists.

Make sure the model’s output is compatible with your current procedures and is simple to use when making decisions.

-

Constant Monitoring and Maintenance

Machine learning models need regular maintenance and observation because they are dynamic. Retrain your model with fresh data on a regular basis to accommodate shifting demand trends and market conditions. Fixing any problems that may come up, like changes in the distribution of data or model deterioration, is another aspect of maintenance.

Conclusion

Training and implementing the model is only the beginning of the process. Machine learning models need constant maintenance. Your model must be continuously monitored, adjusted, and maintained in order to adjust to shifting market conditions and continue to be a useful tool for your company.

In the end, machine learning has advantages for inventory management that go beyond the technology itself. It results in a competitive advantage in the market, higher profitability, and better customer satisfaction. As you begin putting machine learning into practice, keep in mind that it’s about changing the way you manage your inventory going forward and, consequently, the future of your company.

SaaS Development

SaaS Development Web Application Development

Web Application Development Mobile Application Development

Mobile Application Development Custom Software Development

Custom Software Development Cloud Development

Cloud Development DevOps Development

DevOps Development MVP Development

MVP Development Digital Product Development

Digital Product Development Hire Chatbot Developers

Hire Chatbot Developers Hire Python Developers

Hire Python Developers Hire Django Developers

Hire Django Developers Hire ReactJS Developers

Hire ReactJS Developers Hire AngularJS Developers

Hire AngularJS Developers Hire VueJS Developers

Hire VueJS Developers Hire Full Stack Developers

Hire Full Stack Developers Hire Back End Developers

Hire Back End Developers Hire Front End Developers

Hire Front End Developers AI Healthcare Software Development & Consulting

AI Healthcare Software Development & Consulting Healthcare App Development

Healthcare App Development EHR Software Development

EHR Software Development Healthcare AI Chatbot Development

Healthcare AI Chatbot Development Telemedicine App Development Company

Telemedicine App Development Company Medical Billing Software Development

Medical Billing Software Development Fitness App Development

Fitness App Development RPM Software Development

RPM Software Development Medicine Delivery App Development

Medicine Delivery App Development Medical Device Software Development

Medical Device Software Development Patient Engagement Software Solutions

Patient Engagement Software Solutions Mental Health App Development

Mental Health App Development Healthcare IT Consulting

Healthcare IT Consulting Healthcare CRM Software Development

Healthcare CRM Software Development Healthcare IT Managed Services

Healthcare IT Managed Services Healthcare Software Testing services

Healthcare Software Testing services Medical Practice Management Software

Medical Practice Management Software Outsourcing Healthcare IT Services

Outsourcing Healthcare IT Services IoT Solutions for Healthcare

IoT Solutions for Healthcare Medical Image Analysis Software Development Services

Medical Image Analysis Software Development Services Lending Software Development Services

Lending Software Development Services Payment Gateway Software Development

Payment Gateway Software Development Accounting Software Development

Accounting Software Development AI-Driven Banking App Development

AI-Driven Banking App Development Insurance Software Development

Insurance Software Development Finance Software Development

Finance Software Development Loan Management Software Development

Loan Management Software Development Decentralized Finance Development Services

Decentralized Finance Development Services eWallet App Development

eWallet App Development Payment App Development

Payment App Development Money Transfer App Development

Money Transfer App Development Mortgage Software Development

Mortgage Software Development Insurance Fraud Detection Software Development

Insurance Fraud Detection Software Development Wealth Management Software Development

Wealth Management Software Development Cryptocurrency Exchange Platform Development

Cryptocurrency Exchange Platform Development Neobank App Development

Neobank App Development Stock Trading App Development

Stock Trading App Development AML software Development

AML software Development Web3 Wallet Development

Web3 Wallet Development Robo-Advisor App Development

Robo-Advisor App Development Supply Chain Management Software Development

Supply Chain Management Software Development Fleet Management Software Development

Fleet Management Software Development Warehouse Management Software Development

Warehouse Management Software Development LMS Development

LMS Development Education App Development

Education App Development Inventory Management Software Development

Inventory Management Software Development Property Management Software Development

Property Management Software Development Real Estate CRM Software Development

Real Estate CRM Software Development Real Estate Document Management Software

Real Estate Document Management Software Construction App Development

Construction App Development Construction ERP Software Development

Construction ERP Software Development