How AI is Transforming Logistics: Key Benefits for Businesses

- March 12, 2025

-

7241 Views

- by Ishan Vyas

Table of Contents

It’s no secret that artificial intelligence (AI) has been integrated into our culture in the modern day. AI has shown its incredibly creative ability to help us maximise efficiency in many different sectors of our lives, from drone-delivered parcels from Amazon to automated grocery to automated suggestions that finish our sentences.

AI’s innovations have also improved business across a wide range of industries. AI has revolutionised supply and demand chain and logistics operations. Indeed, according to a McKinsey analysis, AI will establish a whole new “logistics paradigm” by 2030 as it continues to surpass humans in repetitive but crucial activities. Solutions for developing logistics softwares are becoming increasingly necessary as a result of the unexpected difficulties in shipping that are currently occurring.

AI-powered solutions, such as warehouse automation, are already increasing safety by 90% and reducing operating costs by up to 50%. AI has a quantifiable effect on the industry in this way.

This article will explore how artificial intelligence (AI) is addressing important logistics issues, such as better demand forecasting and route optimisation, and how it is opening the door to a more effective, flexible logistics environment.

Role of Artificial Intelligence in Revolutionizing Logistics

AI in logistics refers to the application of machine learning, predictive analytics, and intelligent algorithms to enhance operations. It’s not just automation. It assists logistics firms in lowering risks, enhancing performance, and forecasting future trends.

By fostering innovation at every level of the supply chain, artificial intelligence (AI) is revolutionising the logistics sector. AI is now the foundation of modern logistics operations, enabling improved decision-making and automating repetitive processes.

Large volumes of data are used by the technology to enhance procedures. It contributes to cost savings and increased efficiency. Because of this, it is crucial for companies looking to maintain their competitiveness.

Why Logistics Needs AI Today?

Demands on the logistics sector are constantly rising, and they include improved client experiences, lower prices, and quicker deliveries. Conventional systems frequently find it difficult to adjust to these intricacies, which leads to inefficiency and lost opportunities.

Here’s where AI comes in. It provides cutting-edge resources to address significant issues.

-

Enhanced Operational Efficiency

AI lowers human mistakes, automates procedures, and gets rid of manual inefficiencies.

-

Real-Time Decision-Making

Businesses may become more responsive by using AI to make data-driven decisions instantaneously.

-

Scalability

As a firm expands, AI solutions can readily adjust to meet changing demand.

AI is far more than a tool. It aids logistics firms in increasing accuracy, dependability, and profitability.

Top Benefits of Integrating AI in Logistics

When items are stored, transported, and distributed, a vast amount of data is produced. The most crucial data points include temperature, location in real-time, transit costs, and transporter availability. Although there are numerous other ways AI might enhance logistics, it is evident how it may affect customer satisfaction through logistics and the associated on-time delivery. These are covered in more detail below.

-

AI for Inventory and Warehouse Management

Logistics managers can find incoming orders with longer than planned fulfillment times with the use of AI-powered warehouse management software. In order to determine which products are suitable for the items that will be supplied, they can share information about at-risk orders with fulfilment managers. They can also move the stocking location for items so that they are grouped into categories that are frequently ordered together. Additionally, the intelligent AI capabilities are designed to offer customisable email acknowledgements for revisions and new orders, as well as concise and rational summaries of the pertinent order revision histories.

-

Demand Accuracy

Demand forecasters can use the data from AI-integrated logistics software to spot production delays in final items. Logistics managers can also use the information obtained from demand forecasting tools to prioritise the shipment of goods that will affect the overall profit and satisfaction of consumers.

-

Overstock Optimization

Based on past and present demand data, manufacturers can enhance inventory levels by utilising AI-based predictive analytics. This can cut down on excess inventory and avoid stockouts.

-

Fulfillment Efficiency

AI helps warehouses become more efficient, which increases fulfilment rates. To help expedite fulfilment, it suggests flooring patterns and worker pathways after analysing historical demand data to identify the most effective position for specific commodities. AI can be used by warehouse managers to assess whether there is waste space and whether the delivery containers are filled with the appropriate number of products.

-

Order Accuracy

In order to help detect and prevent worker errors, such as removing the incorrect items from warehouses or delivering goods to the incorrect locations, logistics organisations and manufacturers are training AI systems using data collected by cameras and sensors.

These systems can also be used to analyse data that has been collected to determine whether there are many mistakes that could be avoided by changing the design or process, such as improving employee training, changing the packaging to custom boxes, or placing products more strategically based on demand.

-

Picking Optimization

When warehouse workers gather products to fulfil an order, AI can help optimize product picking by recognising order patterns and suggesting that the things that are frequently ordered together be moved to the same area of the storage facility. Another way AI-powered demand projections can help enhance product selection is by suggesting that things with an earlier due date, like perishable items or orders that are time-sensitive, are placed at the most appropriate portions of the warehouse.

-

Label Automation

The traditionally time-consuming and error-prone process of creating shipping labels can be automated with GenAI tools. GenAI products can handle multilingual and international shipping requirements and can be included into warehouse and logistics management software.

-

Route Optimization

AI optimises delivery routes, cutting down on consumption of fuel and transit times. Additionally, smarter routing improves delivery reliability and reduces vehicle wear.

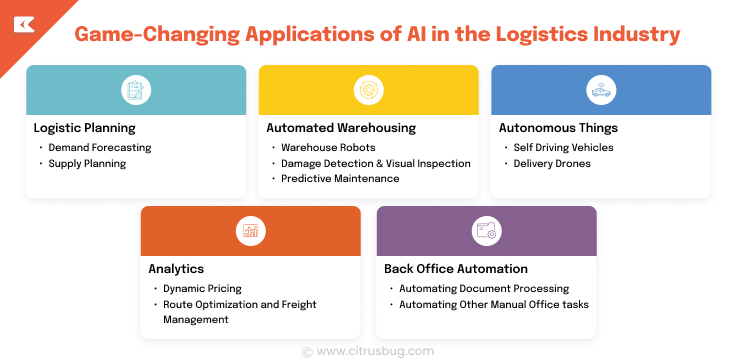

Game-Changing Applications of AI in the Logistics Industry

-

Automated Warehousing

AI-powered robotics and machine learning streamline warehouse operations by automating inventory management, order fulfillment, and storage, significantly reducing labor costs and improving efficiency. The benefits of AI in logistics include faster processing and minimized errors in warehouse operations. -

Forecasting Demand

Artificial Intelligence analyzes historical data, market trends, and external factors to accurately predict demand fluctuations. This ensures optimal inventory levels, reducing stockouts and overstocking while enhancing supply chain efficiency. -

Damage Detection and Predictive Maintenance

AI-driven image recognition and IoT sensors detect potential equipment failures or damaged goods in real time. Predictive maintenance minimizes downtime, lowers repair costs, and enhances overall logistics efficiency. -

Optimization at the Stock Level

By examining current demand, supply chain limitations, and storage capacity, artificial intelligence optimises stock distribution. By ensuring that inventory is distributed effectively, holding costs are decreased and order fulfilment rates are raised. -

Optimization of the Supply Chain

Through data analysis from multiple sources, disruption prediction, and proactive strategy recommendations, artificial intelligence (AI) improves end-to-end supply chain visibility. Companies that use AI in logistics can save money and increase agility. -

Adaptive Pricing

In order to make dynamic price adjustments, AI-driven pricing models examine demand trends, market conditions, and rival pricing. This guarantees pricing strategies that are competitive and optimize revenue and customer pleasure. -

Optimization of Routes

To find the most efficient routes, AI-powered route optimisation examines delivery limitations, traffic, and weather. This minimises the impact on the environment, improves delivery speed, and lowers fuel costs. -

Automating Document Processing

AI-powered OCR and NLP systems automate compliance checks, invoice verification, and customs clearance, streamlining document processing. This improves overall logistical efficiency, speeds up procedures, and lowers manual error rates.

How Logistics Companies Can Start Embracing AI Innovation Step-by-Step?

Although AI has many advantages for logistics, its application requires detailed planning and execution. Logistics firms may find it difficult to adjust to this shift. This is where the special requirements of the logistics sector can be met with the assistance of a reliable AI development firm.

Step 1: Identify Key Challenges and AI Use Cases

Knowing which logistics problems AI can resolve is the first step. Businesses require a strategic strategy whether they are automating document processing, enhancing inventory management, or optimising delivery routes. Professionals with knowledge of AI-powered logistics solutions are able to evaluate existing processes and suggest the most effective uses of AI.

Step 2: Strengthen Data Infrastructure

High-quality data is essential for AI to work efficiently. Logistics companies need to compile, clean, and organise data from a variety of sources, including supply chain logs, GPS monitoring, and warehouse management systems. Accurate insights for improved decision-making are ensured by sophisticated data analytics platforms and AI-powered solutions.

Step 3: Choose the Right AI Technologies

Different AI solutions are needed for different logistics problems. Computer vision can help detect damage, while machine learning helps forecast changes in demand. Working with AI experts guarantees that the appropriate technologies are chosen and tailored to meet particular business requirements.

Step 4: Implement a Pilot Program

Before full-scale adoption, testing AI solutions in a controlled setting helps validate effectiveness. Before implementing AI widely, logistics organisations can assess its effects, improve their methods, and resolve any issues with a well-designed pilot program.

Step 5: Ensure Seamless System Integration

AI must seamlessly interact with current logistics technologies, including ERP, TMS, and WMS, in order to provide the most value. AI can improve operational efficiency without interfering with conventional procedures thanks to clever integration frameworks and API-driven solutions.

Step 6: Focus on Workforce Training and Adoption

It takes people, not just technology, to successfully integrate AI. Employees must comprehend how AI improves their jobs. Improved productivity and seamless adoption are guaranteed via interactive workshops, hands-on training, and ongoing support.

Step 7: Monitor, Optimize, and Scale AI Solutions

AI implementation doesn’t end with deployment. Continuous monitoring, performance analysis, and iterative improvements keep AI models efficient and relevant. As logistics companies grow, scalable AI solutions help expand automation, optimize operations, and maintain a competitive edge.

Logistics companies may embrace AI-driven innovations with the least amount of risk and the greatest amount of efficiency by utilising the experience of an AI development company. A well-thought-out strategy guarantees a seamless transition, allowing logistics to fully benefit from AI while maintaining an advantage in a changing market.

How Citrusbug Technolabs Can Help?

At Citrusbug Technolabs, we combine deep technical expertise with a tailored approach to deliver AI-driven logistics solutions that maximize ROI and optimize operational efficiency. Our team ensures seamless AI adoption through:

Proven Expertise in AI for Logistics

With extensive experience in developing AI-powered logistics solutions, we address industry-specific challenges such as route optimization, demand forecasting, and warehouse automation while delivering measurable business outcomes.

Comprehensive End-to-End Support

From initial consultation and AI strategy development to system integration and ongoing support, we ensure a smooth transition at every stage of AI implementation, aligning technology with business goals.

Scalable and Custom AI Solutions

Our AI models are designed to integrate seamlessly with existing logistics platforms, providing modular and scalable solutions that grow with your business needs while enhancing efficiency.

Client-Centric Collaboration

We work closely with logistics companies to understand unique challenges, ensuring AI solutions are customized to meet specific operational requirements and drive meaningful impact.

Efficient and Cost-Effective Delivery

Leveraging cutting-edge AI tools and development frameworks, we deliver high-quality solutions on time, reducing operational costs and eliminating inefficiencies caused by delays.

With Citrusbug Technolabs as your AI development partner, you can confidently embrace AI-driven innovations and gain a competitive edge in the logistics industry.

SaaS Development

SaaS Development Web Application Development

Web Application Development Mobile Application Development

Mobile Application Development Custom Software Development

Custom Software Development Cloud Development

Cloud Development DevOps Development

DevOps Development MVP Development

MVP Development Digital Product Development

Digital Product Development Hire Chatbot Developers

Hire Chatbot Developers Hire Python Developers

Hire Python Developers Hire Django Developers

Hire Django Developers Hire ReactJS Developers

Hire ReactJS Developers Hire AngularJS Developers

Hire AngularJS Developers Hire VueJS Developers

Hire VueJS Developers Hire Full Stack Developers

Hire Full Stack Developers Hire Back End Developers

Hire Back End Developers Hire Front End Developers

Hire Front End Developers AI Healthcare Software Development & Consulting

AI Healthcare Software Development & Consulting Healthcare App Development

Healthcare App Development EHR Software Development

EHR Software Development Healthcare AI Chatbot Development

Healthcare AI Chatbot Development Telemedicine App Development Company

Telemedicine App Development Company Medical Billing Software Development

Medical Billing Software Development Fitness App Development

Fitness App Development RPM Software Development

RPM Software Development Medicine Delivery App Development

Medicine Delivery App Development Medical Device Software Development

Medical Device Software Development Patient Engagement Software Solutions

Patient Engagement Software Solutions Mental Health App Development

Mental Health App Development Healthcare IT Consulting

Healthcare IT Consulting Healthcare CRM Software Development

Healthcare CRM Software Development Healthcare IT Managed Services

Healthcare IT Managed Services Healthcare Software Testing services

Healthcare Software Testing services Medical Practice Management Software

Medical Practice Management Software Outsourcing Healthcare IT Services

Outsourcing Healthcare IT Services IoT Solutions for Healthcare

IoT Solutions for Healthcare Medical Image Analysis Software Development Services

Medical Image Analysis Software Development Services Lending Software Development Services

Lending Software Development Services Payment Gateway Software Development

Payment Gateway Software Development Accounting Software Development

Accounting Software Development AI-Driven Banking App Development

AI-Driven Banking App Development Insurance Software Development

Insurance Software Development Finance Software Development

Finance Software Development Loan Management Software Development

Loan Management Software Development Decentralized Finance Development Services

Decentralized Finance Development Services eWallet App Development

eWallet App Development Payment App Development

Payment App Development Money Transfer App Development

Money Transfer App Development Mortgage Software Development

Mortgage Software Development Insurance Fraud Detection Software Development

Insurance Fraud Detection Software Development Wealth Management Software Development

Wealth Management Software Development Cryptocurrency Exchange Platform Development

Cryptocurrency Exchange Platform Development Neobank App Development

Neobank App Development Stock Trading App Development

Stock Trading App Development AML software Development

AML software Development Web3 Wallet Development

Web3 Wallet Development Robo-Advisor App Development

Robo-Advisor App Development Supply Chain Management Software Development

Supply Chain Management Software Development Fleet Management Software Development

Fleet Management Software Development Warehouse Management Software Development

Warehouse Management Software Development LMS Development

LMS Development Education App Development

Education App Development Inventory Management Software Development

Inventory Management Software Development Property Management Software Development

Property Management Software Development Real Estate CRM Software Development

Real Estate CRM Software Development Real Estate Document Management Software

Real Estate Document Management Software Construction App Development

Construction App Development Construction ERP Software Development

Construction ERP Software Development