Custom Mobile App Development for Manufacturing: Everything You Need to Know

- August 20, 2025

-

1441 Views

- by Ishan Vyas

Table of Contents

- What is Manufacturing App Development?

- Types of Manufacturing Mobile Apps

- Key Features and Benefits of Manufacturing Mobile Apps

- How Custom Mobile Apps Enhance Manufacturing Businesses

- Estimated Cost of Manufacturing App Development

- Challenges to Expect and How to Overcome Them

- Conclusion: Empower Your Manufacturing Business with a Custom App by Citrusbug

Manufacturing is becoming more complex and fast-paced. To keep up, companies need smart tools that improve visibility, reduce delays, and support better decisions. This is where manufacturing app development becomes essential.

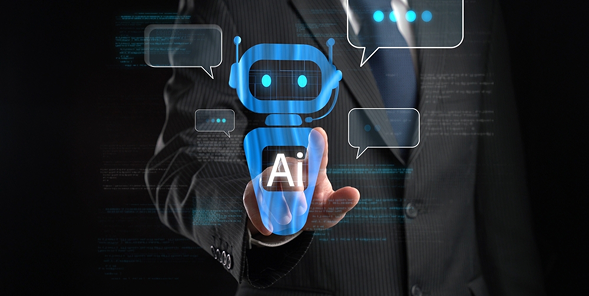

As the smart manufacturing market is expected to grow from $249.5 billion in 2021 to $860 billion by 2031, it’s clear that mobile-driven digital transformation is gaining traction throughout the industry. Custom mobile apps with features like real-time tracking, AI insights, and IoT integration aid manufacturers to work smarter and faster.

Whether it is inventory control or predictive maintenance, mobile apps will enhance the process, reduce the cost, and increase product quality. To manufacturers, they are taking center stage in a long-term digital transformation.

What is Manufacturing App Development?

Manufacturing app development refers to the process of building custom mobile applications tailored to the unique needs of the manufacturing industry. Such applications will address the business issues of operational concerns of production monitoring, inventory management, equipment maintenance, and quality control- right at the smartphone or the tablet.

Unlike mobile tools, manufacturing apps aim at solving very specific problems as opposed to general-purpose mobile tools. An example is that they allow workers to enter problems live, managers to view real-time dashboards, and teams to monitor the productivity of the factory floor. Due to the fast-developing rates of mobile application development services, such solutions are becoming a necessity in the modern, agile manufacturing sphere.

With an increasing shift of manufacturers towards smart factories and increased automation, the market needs of a bespoke digital tool continue to expand. Not only do custom manufacturing applications make the way companies conduct their operations and activities more visible and efficient, but also keep them at the edge of competition in a growingly technology-driven market.

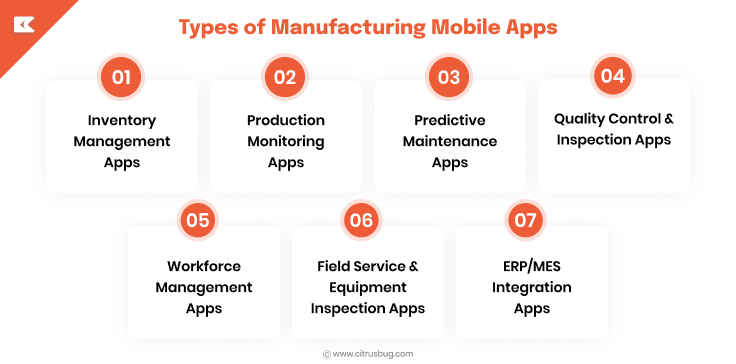

Types of Manufacturing Mobile Apps

Custom mobile apps in manufacturing are built to support specific workflows, machinery, and team operations. The following are some of the most popular forms of applications used in the recent manufacturing environment:

1. Inventory Management Apps

Inventory management apps help track raw materials, components, and finished goods across warehouses. It has features such as scanning of barcodes, real-time stock updates, and alerts when the stock is low to enable it to control the inventory better.

With the rise of AI for inventory management, these apps now offer smarter forecasting, improved accuracy, and smoother supply chain coordination. They have become essential in modern mobile application development for manufacturing.

2. Production Monitoring Apps

Production monitoring apps give managers instant access to key operational data through mobile dashboards. These tools show real-time metrics like machine utilization, shift performance, and production output. By identifying bottlenecks and tracking underperforming assets early, manufacturers can respond quickly to issues, improve throughput, and maintain consistent product quality.

3. Predictive Maintenance Apps

These apps assist teams in identifying possible equipment problems before they cause breakdowns. Predictive maintenance apps alert staff when IoT sensors or machine logs indicate servicing is due. This proactive method aids in minimizing unplanned downtime, reducing maintenance costs, and prolonging the lifespan of vital equipment.

4. Quality Control & Inspection Apps

These apps support quality checks during production by allowing workers to log defects, capture photos, and complete digital checklists. Data syncs to a central system, ensuring compliance and traceability. With the help of custom NLP, some apps can automatically categorize issues or generate quick summaries, saving time on manual reporting.

5. Workforce Management Apps

Factory teams become manageable because of the mobile apps that monitor their attendance, shifts, and tasks. Smartphones or tablets will allow employees to report back to the shop floor and allow them to log or make an update on the progress of their duties. In turn, managers will be able to track productivity and whether the workforce is available without using manual paperwork.

6. Field Service & Equipment Inspection Apps

These apps also streamline equipment checks and audits carried out by the field engineers and service technicians. Tools like fieldServicely provide digital checklists, photo uploads, and guided form completion, with offline data capture that can be synced later. This increases the accuracy of reporting and improves the consistency of data recording in the inspection, even in far locations.

7. ERP/MES Integration Apps

These apps integrate mobile-based devices with central enterprise systems such as ERP and MES systems. Managers are able to see production plans, authorize activities, and receive up-to-date information on a desktop, laptop, or even a smartphone. Such high levels of integration enhance co-operation between the shop floor and the leadership and lead to agility and responsiveness in the operations.

Key Features and Benefits of Manufacturing Mobile Apps

Manufacturing app development plays a vital role in modernizing operations and improving efficiency across the production line. It is not just about converting paper forms into digital versions. Manufacturers can use these types of apps to control essential functions such as production and inventory, quality assurance, and workforce synchronization in a smarter, more interconnected manner.

These are the key features listed below and can be greatly beneficial to your manufacturing company.

1. Real-Time Data Access and Analytics

Custom manufacturing apps have the advantage of immediately providing production indicators, machine-related variables, and performance KPIs. Managers are capable of making quick decisions as Dashboards can be accessed on the move. This omniscience increases the efficiency of the processes, assists in constant improvement initiatives of the factory floor, and lowers idle time.

2. Predictive Maintenance Alerts

Modern mobile app development for manufacturing can identify wear trends with the help of IoT sensors and machine learning, thus avoiding future failures. Predictive maintenance alerts help teams take corrective action before problems worsen, as they minimize unplanned downtimes. This allows businesses to reduce expenses and increase the lifetime of equipment by carrying out proactive repairs. A lot of organizations are already depending on AI software development solutions to build these smart maintenance systems.

3. Seamless ERP and MES Integration

The capability to integrate with the current ERP or MES systems is also one of the biggest advantages of manufacturing app development within manufacturing firms. Integration can be used to synchronize production data, inventory, and worker updates automatically. The automation eliminates the need to make manual data entry, which increases the level of accuracy and prevents discrepancies within various departments.

4. Offline Functionality and Rugged Device Support

Most manufacturing plants operate in areas where connectivity is either unstable or poor. Mobile-based apps allow customers to use vital functions even without an Internet connection, and every detail would be synced automatically once the connection is available. With eSim technology, users can switch networks seamlessly, ensuring uninterrupted connectivity and app functionality anywhere. In addition to that, the apps can be used with rugged monitors that work under tough circumstances.

5. Customizable Workflows and Role-Based Access

The processes in every manufacturing company are unique. With custom applications, you can design a unique workflow for different users and departments. Supervisors of shifts, quality inspectors, field technicians, and all other users have only essential information and, as a result, can work more securely and efficiently.

6. Faster, Paperless Reporting and Audits

With mobile-enabled forms, automated logging facilities, and image-capture features, organizations can improve the accuracy of reporting with the concomitant reduction in both the time it takes to achieve and the availability of such activities. In compliance-sensitive and heavily regulated manufacturing industries, these forms of technology drive up compliance audit efficacy, minimizing paperwork levels and enhancing traceability as a whole.

How Custom Mobile Apps Enhance Manufacturing Businesses

Custom-built mobile apps go far beyond standard tools. They are built around your unique processes, teams, and machines. Here’s how they can impact your business:

| Business Area | Enhancement Provided |

|---|---|

| Production | Real-time monitoring, faster bottleneck identification |

| Quality Assurance | On-the-spot defect reporting with photos and data logs |

| Inventory | Barcode-based scanning and stock reconciliation |

| Maintenance | Scheduled maintenance alerts and real-time fault logging |

| Workforce | Efficient task assignments, shift tracking, and mobile timesheets |

Moreover, when AI is integrated into these apps, it provides predictive insights, automated quality checks, and intelligent routing of tasks.

Estimated Cost of Manufacturing App Development

The AI app development cost of custom mobile applications is estimated in the range of $20,000 and $200,000. It may differ depending on a number of factors, the complexity of the given app, the presence or absence of third-party integrations, and the nature of the technology stack. The ultimate cost is also determined by whether to develop an iOS or Android app or both.

For manufacturing app development, the cost typically ranges from $25,000 to $150,000. This depends on specific business needs, the back-end complexity, and functions that need to be supported, like real-time tracking and predictive maintenance. These features can increase the up-front expenditure, yet they can result in higher productivity and more net returns.

Here’s a breakdown of what influences the overall cost:

| Cost Factor | Details |

|---|---|

| App Complexity | Basic applications, for example, those that include inventory tracking, will likely cost $25,000 to $40,000. More sophisticated systems that include real-time analytics, the IoT, and dashboards for multiple users may exceed $100,000. |

| Platform Choice | The cost of developing on Android or iOS separately is lower than creating cross-platform or multi-device applications. Cost-effective hybrid applications utilizing React Native or Flutter are available. |

| Backend Integrations | Integration with ERP, MES, or IoT systems will incur an additional spend of $10,000 to $30,000 because of the supplementary ideation, development, and testing work needed. |

| UI/UX Design | In manufacturing setups, having a simple, sensible design is pivotal. As with the case of specialized interfaces, lack of online connectivity, and offline functionality, such design elements can increase costs by $5,000–$15,000. |

| Maintenance & Support | Annual expenditures for updates, support, and new feature integrations after product launch usually fall within the range of 15-20% of the initial development budget. |

Pro Tip: Launching with a Minimum Viable Product (MVP) assists in managing costs for the first few iterations as you measure the app’s effectiveness on your operations.

The price of creating the initial version of a mobile application may also go up as elaborate features are incorporated, including artificial intelligence algorithms, voice commands through NLP, or generative reporting systems. To make these capabilities practical, most companies opt to hire AI engineers who can apply them to the unique manufacturing requirements. Although they can increase the initial costs, these features can greatly boost automation, long-term value, and the overall performance of apps.

Challenges to Expect and How to Overcome Them

Even with all the advantages of custom mobile app development for manufacturing, the process may come with a few challenges. Here’s what to expect, and how to solve them:

Legacy System Integration

Multiple production firms rely on legacy ERP or MES systems, which are incompatible with modern applications.

Solution: Implement APIs or middleware to streamline data flow or use gradual upgrades to modernize underlying systems.

Poor Shop Floor Connectivity

Factory locations often experience poor and unstable internet connectivity, hindering real-time data updates.

Solution: Create offline-first features that allow real-time data updating with local data storage and automatic syncing during reconnection.

Low User Adoption

Poorly designed new tools and a new working interface can lead to a reluctance from employees to adopt these changes, causing a decrease in productivity.

Solution: Provide robust training, tailored to specific user groups, with a focus on a self-explanatory interface, structured menus, and logical workflows.

Data Security Risks

Applications developed for manufacturing industries store and process sensitive production and inventory data, which requires safeguarding.

Solution: Secure logins, encrypted data transfers, and adherence to industry-specific data protection standards provide solutions.

Scope Creep During Development

Without a predefined roadmap, adding extra features can increase expenses and delay the project timeline.

Solution: Begin with an MVP (Minimum Viable Product). Focus on primary functions and refine them through subsequent iterations based on user feedback.

Conclusion: Empower Your Manufacturing Business with a Custom App by Citrusbug

A custom mobile app development for manufacturing is not only a technological improvement, but it is also an investment in the development of operations. It is a strategic move that improves a business’s manufacturing processes, automates tasks, and streamlines operations. By having the right solution, manufacturers can integrate key functions, enhance real-time visibility, and react to fluctuating requirements.

Being a trusted mobile app development company, Citrusbug Technolabs assists its clients in developing smart and scalable mobile solutions to meet their specific requirements. From real-time ERP systems to predictive maintenance and production monitoring, our mobile applications are customized to fit your workflows. Is your company considering upgrading and becoming more operationally effective? We would be happy to help you along your path toward a smarter, more connected manufacturing floor.

SaaS Development

SaaS Development Web Application Development

Web Application Development Mobile Application Development

Mobile Application Development Custom Software Development

Custom Software Development Cloud Development

Cloud Development DevOps Development

DevOps Development MVP Development

MVP Development Digital Product Development

Digital Product Development Hire Chatbot Developers

Hire Chatbot Developers Hire Python Developers

Hire Python Developers Hire Django Developers

Hire Django Developers Hire ReactJS Developers

Hire ReactJS Developers Hire AngularJS Developers

Hire AngularJS Developers Hire VueJS Developers

Hire VueJS Developers Hire Full Stack Developers

Hire Full Stack Developers Hire Back End Developers

Hire Back End Developers Hire Front End Developers

Hire Front End Developers AI Healthcare Software Development & Consulting

AI Healthcare Software Development & Consulting Healthcare App Development

Healthcare App Development EHR Software Development

EHR Software Development Healthcare AI Chatbot Development

Healthcare AI Chatbot Development Telemedicine App Development Company

Telemedicine App Development Company Medical Billing Software Development

Medical Billing Software Development Fitness App Development

Fitness App Development RPM Software Development

RPM Software Development Medicine Delivery App Development

Medicine Delivery App Development Medical Device Software Development

Medical Device Software Development Patient Engagement Software Solutions

Patient Engagement Software Solutions Mental Health App Development

Mental Health App Development Healthcare IT Consulting

Healthcare IT Consulting Healthcare CRM Software Development

Healthcare CRM Software Development Healthcare IT Managed Services

Healthcare IT Managed Services Healthcare Software Testing services

Healthcare Software Testing services Medical Practice Management Software

Medical Practice Management Software Outsourcing Healthcare IT Services

Outsourcing Healthcare IT Services IoT Solutions for Healthcare

IoT Solutions for Healthcare Medical Image Analysis Software Development Services

Medical Image Analysis Software Development Services Lending Software Development Services

Lending Software Development Services Payment Gateway Software Development

Payment Gateway Software Development Accounting Software Development

Accounting Software Development AI-Driven Banking App Development

AI-Driven Banking App Development Insurance Software Development

Insurance Software Development Finance Software Development

Finance Software Development Loan Management Software Development

Loan Management Software Development Decentralized Finance Development Services

Decentralized Finance Development Services eWallet App Development

eWallet App Development Payment App Development

Payment App Development Money Transfer App Development

Money Transfer App Development Mortgage Software Development

Mortgage Software Development Insurance Fraud Detection Software Development

Insurance Fraud Detection Software Development Wealth Management Software Development

Wealth Management Software Development Cryptocurrency Exchange Platform Development

Cryptocurrency Exchange Platform Development Neobank App Development

Neobank App Development Stock Trading App Development

Stock Trading App Development AML software Development

AML software Development Web3 Wallet Development

Web3 Wallet Development Robo-Advisor App Development

Robo-Advisor App Development Supply Chain Management Software Development

Supply Chain Management Software Development Fleet Management Software Development

Fleet Management Software Development Warehouse Management Software Development

Warehouse Management Software Development LMS Development

LMS Development Education App Development

Education App Development Inventory Management Software Development

Inventory Management Software Development Property Management Software Development

Property Management Software Development Real Estate CRM Software Development

Real Estate CRM Software Development Real Estate Document Management Software

Real Estate Document Management Software Construction App Development

Construction App Development Construction ERP Software Development

Construction ERP Software Development