AI in Manufacturing Statistics: Adoption, Growth, and Future Outlook

- October 9, 2025

-

1105 Views

- by Ishan Vyas

Table of Contents

- How Extensive Is AI Adoption Across the Manufacturing Industry?

- Which Regions Are Leading the Way in AI Manufacturing Adoption?

- AI Market Segmentation in Manufacturing: Hardware, Software, and Services

- What Key Technologies Are Powering AI in Manufacturing?

- What Does the Future Market Outlook for AI in Manufacturing Statistics Look Like?

- Conclusion

Artificial Intelligence (AI) is no longer a future-oriented concept in manufacturing. It is in the process of transforming production lines, factories and supply chains across the globe. From robotics and predictive maintenance, AI is helping manufacturers increase efficiency, reduce costs, and increase productivity. As competition in the global market increases, businesses are increasingly dependent upon AI software development solutions to remain ahead.

This article examines AI in manufacturing statistics, trends in adoption and market growth, the technologies that are driving AI regional adoption and the outlook for AI in the manufacturing sector.

How Extensive Is AI Adoption Across the Manufacturing Industry?

The use of AI in the manufacturing industry is growing rapidly as businesses increasingly recognise the potential of AI to improve efficiency, cut costs, and encourage the development of new products and services. AI in Manufacturing Statistics reveal AI technology is becoming integral to processes across the world:

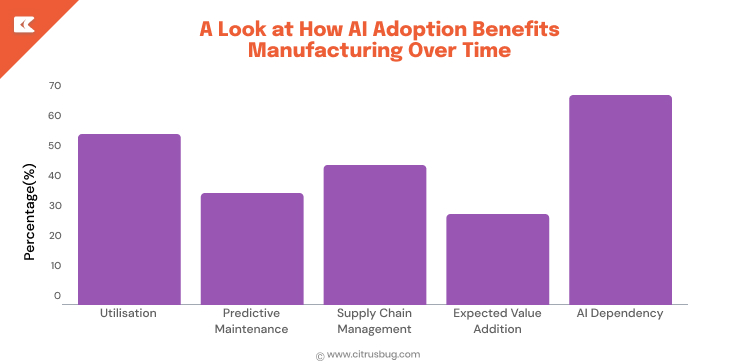

- 56% of the businesses studied in the report by Forbes Advisory are currently using AI tools to improve their business operations.

- 35% of manufacturing companies have implemented AI specifically in the areas of predictive maintenance and quality control.

- Presently, 41% of all manufacturers use AI applications to gather data, analyse, and manage data from supply chains to aid in better management and planning.

- Around 27% of businesses say that AI has already provided tangible value to their operations and 56% anticipate tangible results within the next 2 to 5 years.

- In the U.S. automotive sector, 60% of major companies have incorporated AI technologies into their design and production processes.

Measurable Benefits of AI in Manufacturing

AI adoption is bringing important outcomes for manufacturers:

- Businesses have reported as much as a 50% reduction in production times through the implementation of AI solutions.

- General Electric reduced unplanned downtime by 10–20% by using AI-driven predictive maintenance.

- Predictive maintenance can reduce maintenance costs by 25% and cut unplanned downtime by as high as 30%.

- About 90% of the top machine manufacturers invest heavily in predictive analytics, and machine learning in manufacturing is playing a crucial role in driving better automation and data-driven decision-making.

Current Trends and Industry Insights

- AI manufacturing trends and statistics show that about 44% of the companies in this industry are currently working on AI prototypes.

- As per AI in manufacturing statistics, 93% of businesses believe that artificial intelligence is essential to creating innovation and achieving long-term growth.

- For companies using AI every day, 66% have a high dependence on the latest technologies, and they plan to keep up AI adoption.

- Of the companies that offer AI solutions for the industry, 64% are focused on models that are supervised in response to the growing demand for data-driven decisions.

- Over 60% of manufacturing firms have created a formal strategy to incorporate AI into their processes, signalling a strong commitment to adopting AI for the long-term benefit of their business.

These figures clearly demonstrate the fact that AI can no longer be considered just a technology that was used to test manufacturing. From predictive maintenance and supply chain optimisation to efficiency and technological innovation, AI is shaping the future of manufacturing.

Which Regions Are Leading the Way in AI Manufacturing Adoption?

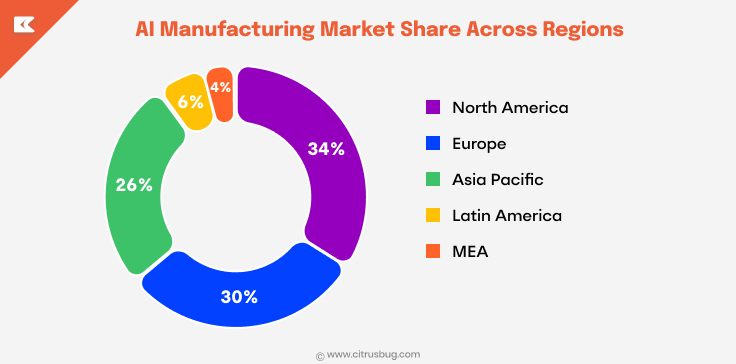

This chart shows the distribution in regional areas for Artificial Intelligence (AI) in manufacturing statistics.

- North America leads with the biggest market share of 34% and proves that the area is on the cutting edge of integrating AI into manufacturing machines and intelligent factories.

- Europe is close to 30% due to the high level of investment in robotics, automation, and AI in production statistics that continue to boost efficiency and innovation.

- Asia Pacific holds a significant 26% that demonstrates the rapid growth of its industrial sector and growing adoption of AI technologies. This positions Asia Pacific as a major participant within AI industrial trends.

- Latin America accounts for 6% which indicates a gradual acceptance, however, there are opportunities to grow as industries evolve.

- Middle East & Africa (MEA) are 4.4% which is a sign of the initial phases of AI implementation in the manufacturing sector, but the potential for growth is anticipated due to the upcoming developments in industrial technology.

In short, North America and Europe dominate the AI in manufacturing statistics; however, Asia Pacific is quickly catching up and positioning itself as a strong growth region. However, Latin America and MEA are in their early stages, but they have the potential for growth in the future.

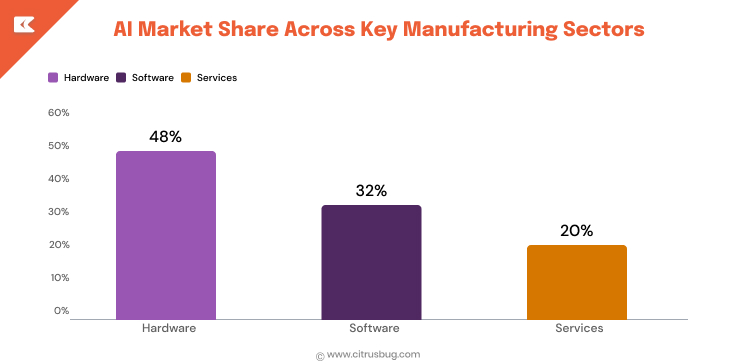

AI Market Segmentation in Manufacturing: Hardware, Software, and Services

Hardware (48%)

Hardware is the leader in the market, with 48% which means that nearly half of AI manufacturing investment is focused on physical components.

It includes robotics powered by AI, advanced sensors, and other smart machines that increase the efficiency and accuracy of manufacturing processes.

The emphasis on hardware indicates that manufacturers are incorporating AI into their existing infrastructure. The upgrade of machinery using AI increases efficiency, reduces errors, and boosts overall performance. The recent AI in Manufacturing Statistics highlight the increasing importance of intelligent hardware in the manufacturing industry.

Software (32%)

Software has a 32% market share that covers AI algorithms and data analytics platforms, along with a decision-support system. These software solutions are crucial to process the huge amount of data generated by AI-equipped hardware.

By analysing this data, software allows predictive maintenance using AI as well as quality control, optimisation of supply chain processes and more intelligent decisions.

This demonstrates the vital importance of AI software to make manufacturing processes more sophisticated and data-based.

Services (20%)

Services make up an additional 20% in the overall market, which includes consultation and system integration, maintenance, as well as continuous assistance to AI technology in the manufacturing industry.

Although smaller in share compared to software and hardware services, they play a significant part in the achievement of AI adoption. They can ensure that AI solutions are implemented effectively and are in sync with current operations.

They also offer long-term support to manufacturers, helping them keep their systems running at a high efficiency, with reliability and smooth performance as AI technologies continue to develop.

What Key Technologies Are Powering AI in Manufacturing?

1. Machine Learning (ML)

What It is & How It’s Used in Manufacturing

In the manufacturing industry, Machine Learning (ML) is among the most extensively used AI techniques. It helps in the ability to predict maintenance and quality controls as well as supply chain efficiency through analysing data patterns.

ML can also help reduce downtime, increase product consistency, and improve efficiency by learning continuously using live data.

Market Size & Forecast

In 2024, the global machine learning segment in the category of “AI for manufacturing” was estimated to be around USD 1,570.1 million. This is projected to increase to around USD 13,499.2 million by 2030. This implies a CAGR of 45.4% from 2025 to 2030.

Another report estimates the “Machine Learning in Manufacturing Market” in the range of USD 892.24 million by 2024. The market is projected to grow to approximately 7,383.03 million in 2031 at a CAGR of 33.35%.

Additionally, 85% of logisticians expect to implement AI/ML in supply chain management in the next five years.

2. Deep Learning (DL)

What It is & How It’s Used in Manufacturing

Deep Learning (DL), one of the subsets of ML, is a step further in automation by using advanced neural networks to tackle complex tasks such as the computer vision system, defects detection along with robot direction.

It can help control quality predictively by analysing sensors and images in real-time. Manufacturers can also utilise DL to forecast demand and for improving operations in the supply chain, thereby increasing efficiency while lowering cost.

Market Size & Forecast

The Deep Learning market overall (across industries) is estimated to be USD 47.89 billion by 2025. It is projected to grow to USD 232.75 billion by 2030, and an estimated CAGR of 37.19%.

The focus is on “Deep manufacturing learning”, one study estimates that the market size was around USD 1.5 billion by 2023 and it will grow to around USD 9.8 billion in 2032. This is a CAGR of 22.5% from 2024 to 2032.

Within the “deep learning market based on application”, the manufacturing sector accounts for approximately 15% of deep-learning applications across different industries.

3. Natural Language Processing (NLP)

What It is & How It’s Used in Manufacturing

The use of Natural Language Processing (NLP) is changing how companies handle unstructured information like maintenance logs, reports and supply chain documents. It allows for better communication, faster documentation, and better insight from text-based data.

NLP can also be used to create chatbots and virtual assistants to improve support for workers and enhance the quality of decision-making.

Market Size & Forecast

There was an NLP part in AI for manufacturing that was 1,287.8 million by 2024. This is projected to be around USD 10,393.9 million by 2030. This is a CAGR of 43.8% between 2025 and 2030.

The overall NLP market was worth approximately USD 59.70 billion by 2024. It is predicted to increase to USD 439.85 billion in 2030, with an annual growth rate of 38.7%.

What Does the Future Market Outlook for AI in Manufacturing Statistics Look Like?

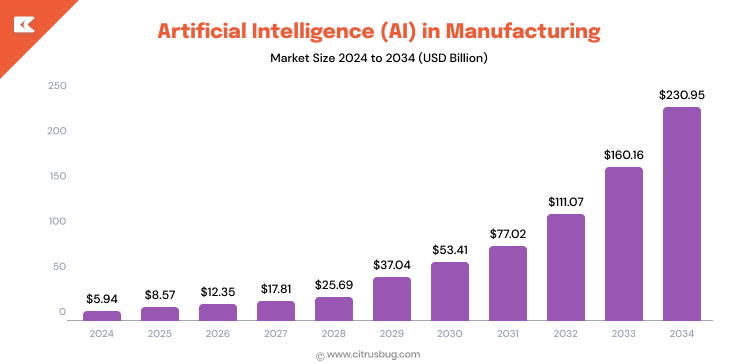

The chart illustrates the projected market growth of Artificial Intelligence (AI) in the manufacturing industry between 2024 and 2034.

In 2024, the world’s AI in Manufacturing Statistics indicates an estimated market worth of USD 5.94 billion that is a reflection of the early stages of its adoption, when industries are beginning to investigate AI for automating processes as well as defect detection and efficiency in production.

The market in 2028 will grow up to USD 25.69 billion, driven by the greater integration of machine vision, robotics and supply chain optimisation, which is proving the effectiveness of AI in reducing costs and operational efficiency.

In 2030, the market increased to USD 53.41 billion, crossing the USD 50 billion, which indicates that AI adoption is shifting from experiments to industrial-scale applications in global factories.

Finally, the global artificial intelligence (AI) in manufacturing market was valued at USD 5.94 billion in 2024 and is projected to surge to approximately USD 230.95 billion by 2034, growing at a compound annual growth rate (CAGR) of 44.2% over the forecast period.

Conclusion

AI is changing manufacturing, increasing efficiency, cutting costs, and enabling better decision-making. In everything from predictive maintenance and deep learning to NLP and more companies are increasingly embracing AI solutions to remain innovative and competitive.

Making investments in AI-powered manufacturing software development allows businesses to integrate intelligent systems, streamline processes, and create tangible value. With the predicted growth, AI is set to become a key component for modern-day, information-driven manufacturing around the world.

SaaS Development

SaaS Development Web Application Development

Web Application Development Mobile Application Development

Mobile Application Development Custom Software Development

Custom Software Development Cloud Development

Cloud Development DevOps Development

DevOps Development MVP Development

MVP Development Digital Product Development

Digital Product Development Hire Chatbot Developers

Hire Chatbot Developers Hire Python Developers

Hire Python Developers Hire Django Developers

Hire Django Developers Hire ReactJS Developers

Hire ReactJS Developers Hire AngularJS Developers

Hire AngularJS Developers Hire VueJS Developers

Hire VueJS Developers Hire Full Stack Developers

Hire Full Stack Developers Hire Back End Developers

Hire Back End Developers Hire Front End Developers

Hire Front End Developers AI Healthcare Software Development & Consulting

AI Healthcare Software Development & Consulting Healthcare App Development

Healthcare App Development EHR Software Development

EHR Software Development Healthcare AI Chatbot Development

Healthcare AI Chatbot Development Telemedicine App Development Company

Telemedicine App Development Company Medical Billing Software Development

Medical Billing Software Development Fitness App Development

Fitness App Development RPM Software Development

RPM Software Development Medicine Delivery App Development

Medicine Delivery App Development Medical Device Software Development

Medical Device Software Development Patient Engagement Software Solutions

Patient Engagement Software Solutions Mental Health App Development

Mental Health App Development Healthcare IT Consulting

Healthcare IT Consulting Healthcare CRM Software Development

Healthcare CRM Software Development Healthcare IT Managed Services

Healthcare IT Managed Services Healthcare Software Testing services

Healthcare Software Testing services Medical Practice Management Software

Medical Practice Management Software Outsourcing Healthcare IT Services

Outsourcing Healthcare IT Services IoT Solutions for Healthcare

IoT Solutions for Healthcare Medical Image Analysis Software Development Services

Medical Image Analysis Software Development Services Lending Software Development Services

Lending Software Development Services Payment Gateway Software Development

Payment Gateway Software Development Accounting Software Development

Accounting Software Development AI-Driven Banking App Development

AI-Driven Banking App Development Insurance Software Development

Insurance Software Development Finance Software Development

Finance Software Development Loan Management Software Development

Loan Management Software Development Decentralized Finance Development Services

Decentralized Finance Development Services eWallet App Development

eWallet App Development Payment App Development

Payment App Development Money Transfer App Development

Money Transfer App Development Mortgage Software Development

Mortgage Software Development Insurance Fraud Detection Software Development

Insurance Fraud Detection Software Development Wealth Management Software Development

Wealth Management Software Development Cryptocurrency Exchange Platform Development

Cryptocurrency Exchange Platform Development Neobank App Development

Neobank App Development Stock Trading App Development

Stock Trading App Development AML software Development

AML software Development Web3 Wallet Development

Web3 Wallet Development Robo-Advisor App Development

Robo-Advisor App Development Supply Chain Management Software Development

Supply Chain Management Software Development Fleet Management Software Development

Fleet Management Software Development Warehouse Management Software Development

Warehouse Management Software Development LMS Development

LMS Development Education App Development

Education App Development Inventory Management Software Development

Inventory Management Software Development Property Management Software Development

Property Management Software Development Real Estate CRM Software Development

Real Estate CRM Software Development Real Estate Document Management Software

Real Estate Document Management Software Construction App Development

Construction App Development Construction ERP Software Development

Construction ERP Software Development