Digital Transformation in Manufacturing in 2026: Benefits & Examples

- August 27, 2025

-

1161 Views

- by Ishan Vyas

Table of Contents

- What is Digital Transformation in Manufacturing?

- Why Digital Transformation Matters for the Manufacturing Industry in 2026

- Benefits of Digital Transformation in Manufacturing in 2026

- Key Technologies Driving Digital Transformation in Manufacturing

- Focus Areas for Digital Transformation in Industrial Manufacturing

- Real-World Digital Transformation Examples in Manufacturing

- Challenges of Digital Transformation in Manufacturing

- Why Choose Citrusbug Technolabs for AI Manufacturing Software Development?

- Future of Digital Transformation in Manufacturing Beyond 2026

- Conclusion

The transformation of the manufacturing industry might be the most obvious change that has occurred in the recent past. Machines are no longer completing tasks, but they learn, predict and make faster decisions than ever teams could. And this is the truth of digital transformation in manufacturing in 2026.

The question is no longer whether to use new technologies, but how fast you can implement them in order to remain competitive. Manufacturers that have adopted this change are experiencing less production delays, enhanced supply chain resilience and actual reduction in costs. Those that wait? They are at risk of losing it in an industry where agility is the new norm.

This guide will explain what exactly digital transformation in manufacturing looks like, the benefits it brings, the technologies driving the change, and practical examples you can use to transform your own business.

What is Digital Transformation in Manufacturing?

Digital transformation in manufacturing is the process of moving from traditional, manual-based production to automated and connected manufacturing supported by data and advanced technologies. It is not simply about upgrading machines or digitizing paperwork. It is the creation of a more intelligent ecosystem, where people, processes, and technology operate together harmoniously.

Under the digital transformation in manufacturing industry, data turns into the basis of any decision. Sensors give real-time data, artificial intelligence forecasts the maintenance before it happens, and linked supply chains respond immediately to changes in the market. The outcome is a quicker production, a decrease in the number of mistakes, and agility.

To start this journey, many manufacturers find solutions such as AI automation in business or machine learning models that maximize inventory, quality control, and logistics. The final aim is to develop an efficient, resilient, and competitive environment for rapidly evolving markets.

Why Digital Transformation Matters for the Manufacturing Industry in 2026

In 2026, manufacturing is no longer about whether to adopt digital solutions but how quickly companies can implement them. 98% of manufacturers are digitally transforming, compared to 78% in 2019.

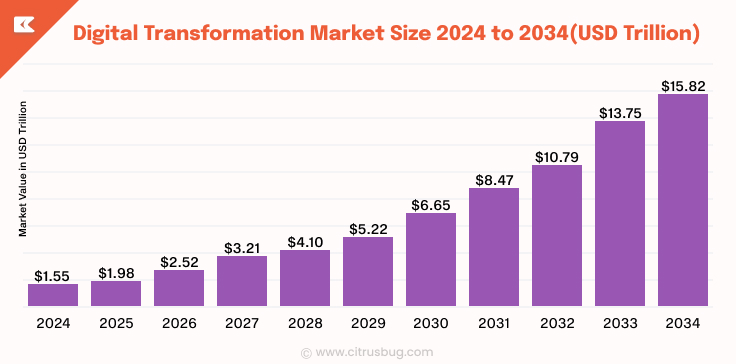

There are rising investments in technologies, which represent 30% of operating budgets, with the highest returns on investments reported in cloud, generative AI, and 5G. Worldwide, the digital transformation market value was estimated to reach $1.07 trillion in 2024 and will later surge up to $15.82 trillion in 2034, thus making it a necessary move to remain competitive.

Key reasons why digital transformation matters today:

- Operational Efficiency: AI, IoT sensors and real-time data are being used to reduce downtime and cut waste.

- Profitability Gains: More than half of manufacturers indicate profitability successes with digital activity leading to real ROI.

- Supply Chain Resilience: inked networks bring visibility and quicker reaction to disruptions.

- Workforce Empowerment: Digital technologies help employees to be set free from routine activities and make decisions based on real data.

- Manufacturing trends: Generative AI, digital twins, and predictive analytics are transforming factory design, monitoring, and optimization.

- Sustainability: Utilizing the energy efficiently and minimizing waste of resources will contribute to global green ends.

Digitalisation in manufacturing is about creating a business that is resilient, agile, and future-proof, that succeeds in a rapidly changing market. Businesses that have adopted it in the present day are the ones that will lead the industry in the future, whereas those that hold back may lose out.

Benefits of Digital Transformation in Manufacturing in 2026

The effects of digital transformation in manufacturing industry are strong in production, supply chains, and decision-making. It is about automating processes, enhancing their efficiency, and making them more efficient, safer, and competitive in 2026.

Efficiency and Productivity

IoT predictive maintenance can be used to minimize unpredictable downtimes by 70% and maintenance expenditures by 30%. This enables teams to work on more value-adding tasks rather than spend time troubleshooting.

Smarter Supply Chains

New digital tools enable better management of the supply chain and when manufacturers apply IoT in inventory tracking, it provides real-time visibility and enhanced responsiveness.

AI-Driven Returns

More industrial manufacturers are leveraging generative AI and increasingly more are planning to increase investment in AI and machine learning. They are tools that streamline the processes, minimize errors and improve the quality of products.

Higher ROI from Digital Investments

Companies are generating more profitability on their digital investments, demonstrating that manufacturing digital transformation pays off with quantifiable financial gains.

Manufacturing data as an Asset

Manufacturing data is growing at an unprecedented rate by offering cost-effective predictive maintenance, inventory management, and process optimization. When integrated with enterprise systems such as SAP maintenance, this data becomes even more valuable, helping manufacturers track equipment health, schedule repairs proactively, and minimize downtime. The effective use of this data fuels operational excellence and innovative processes.

Beyond machines and automation, digital transformation also empowers employees by reducing repetitive tasks and enabling upskilling opportunities. Customers benefit from faster delivery, better product customization, and improved service.

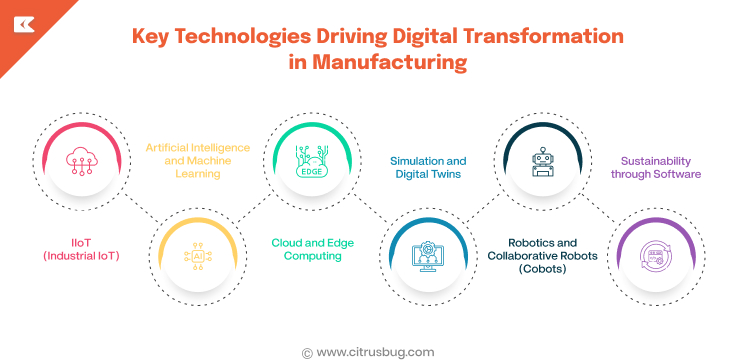

Key Technologies Driving Digital Transformation in Manufacturing

Digitalization in manufacturing relies on a variety of technologies that turn factories into faster, smarter and more connected machines. There is a different role for each technology to play in the simplification processes, error reduction, and productivity enhancement.

1. IIoT (Industrial IoT)

Edge computing, real-time insights, and sensors are the keys to predictive maintenance and operational insight. The IIoT allows manufacturers to predict problems before they interfere with production and keep track of the performance of their equipment.

2. Artificial Intelligence and Machine Learning

AI and ML can be used in predictive maintenance and demand forecasting, process optimization, and quality control. These are some of the AI trends that have become significant in factories today, as they allow the machine team to make decisions using data faster and precisely.

3. Cloud and Edge Computing

Cloud and edge computing enable scalable analytics with immediate access to critical operating data. By integrating all the elements of the production line, manufacturers are able to make quicker, more intelligent decisions, whilst still retaining uncompromised control over the complicated processes.

4. Simulation and Digital Twins

Digital replica modeling of the equipment and processes also allows manufacturers to test scenarios and workflow improvement and reduce risk by first implementing changes virtually through simulation before doing so on the factory floor, leading to greater planning and operational efficiencies.

5. Robotics and Collaborative Robots (Cobots)

Automation technology, especially robotics, makes processes more accurate and pliable, which means teams can work on more valuable tasks and machines can perform repetitive or potentially dangerous tasks, improving overall productivity and safety.

6. Sustainability through Software

Smart digital solutions enable factory operators to monitor energy consumption, minimize wastage, and convert into carbon-neutral facilities in the long term with consideration to sustainability and corporate responsibility agendas.

When it comes to manufacturing digital transformation, integrating those technologies is the most important. In businesses interested in AI-powered solutions, collaboration with an AI software development agency can streamline the process and help make technologies most effective.

Focus Areas for Digital Transformation in Industrial Manufacturing

Digital transformation in manufacturing is about improving efficiency, agility, and competitiveness. Investing in the right area helps companies maximize their investments.

Smart Factories

Connected production lines create real-time visibility, operational transparency, quicker decisions in all processes, and minimize manual errors and enhance coordination.

Predictive Maintenance

AI forecasts possible equipment breakdowns before they can happen, leading to downtime reduction, cost reduction in repairs and even prolonged machinery life.

Digitization of the supply chain

Real-time monitoring and analysis make the supply chain more robust, transparent, and dynamic, and allow it to respond to fluctuations in the market and fluctuating demand much faster.

Upskilling the Teams

Training employees about automation, analytics, and digital tools guarantees a higher level of adoption, improved efficiency, and communication throughout departments.

Customer-Driven Value

Personalized production, workflows, and traceability allow manufacturers to satisfy emerging customer needs and increase satisfaction and loyalty.

These areas are critical to the success of digital transformation in manufacturing because they help companies remain competitive and future-proof.

Real-World Digital Transformation Examples in Manufacturing

The digitalization of the manufacturing industry is transforming industries and allowing companies to innovate, achieve efficiency, and remain competitive. Here are some real-life examples:

-

Automotive Industry

In this sector, major automakers are applying digital twins to the design process simulation, including the process of production. This will minimize the design mistakes, development cycles and enhance teamwork among engineering departments, and also boost the efficiency of the production.

-

Electronics Manufacturing

Predictive quality control using AI is occurring at electronics manufacturing factories. A data-driven approach to manufacturing digital transformation can be achieved by processing production data in real time and identifying defects and minimizing wasted production in order to ensure quality products.

-

Aerospace

Aerospace manufacturers are finding the use of additive manufacturing to enable them to make lighter components, but also more efficient. Such digitalization lowers the cost of materials, accelerates prototyping, and ensures better fuel efficiency, showing how digital transformation in manufacturing sector can help achieve innovation and sustainability.

-

FMCG Sector

The fast-moving consumer goods companies are deploying the IoT-enabled supply chains to monitor inventory, track shipments and respond immediately to shifting demand. This helps in making things more transparent, minimizes all stockout situations and makes the products availed to the customers quicker and with more reliability.

-

Heavy Machinery

Predictive maintenance systems use constant tracking of machines to predict the inclination to failure before it occurs. This reduces downtimes, adds durability to machinery, and adds effectiveness to operations, which proves that digital transformation is practical in the manufacturing sector.

Global giants and startups in various industries are leading the way into the digital manufacturing realm, which shows that establishing digital manufacturing can be implemented on a large scale. A partnership with a custom software development firm can assist businesses in an effective rollout of AI-enabled solutions.

Challenges of Digital Transformation in Manufacturing

There are various challenges associated with the implementation of digital transformation in the manufacturing sector that businesses should negotiate to attain success.

Data Preparation

Low-quality, siloed, or inconsistent data can make adoption slow. Over 60% of manufacturers lack AI-ready data pipelines, and AI development services are the best chance to improve data governance and system modernization.

Fragmented Adoption

Most manufacturers are adopting digital tools in a piecemeal fashion instead of engaging in strategic adoption, which limits the future benefits of overall digital maturity.

Manual-based legacy

A large number of firms still use manual-based systems of configuration and quotation, which makes it tricky to integrate with the newer digital systems.

Third-Party Dependence

Outsourcing of key functions, including cybersecurity, data management, and automation, may create dependency risk.

Proactively solving these issues is important to harness the full potential of digital transformation trends in production and achieve easier and scalable realization.

Why Choose Citrusbug Technolabs for AI Manufacturing Software Development?

Citrusbug Technolabs offers expert AI development services to empower manufacturing companies to embark on a real digital transformation of manufacturing. We offer solutions that integrate superior technology with expertise in the industry to enhance efficiency, flexibility and innovation in operations.

- Industry Expertise: We have expertise in the industry-specific requirements of the manufacturing industry and provide solutions related to workflows and operational requirements.

- Custom Software Development: Our software development business builds scalable and high-performance applications that integrate with your existing systems to improve productivity and operational efficiency within every department or area of focus.

- AI and Automation Knowledge: Our manufacturing app development services can help manufacturers integrate predictive maintenance to optimize their supply chains and make informed decisions off valuable data.

- End-to-End Support: We take you through the whole process, including planning and strategy, to implementation and optimization to yield results and a continuous improvement in the process.

- ROI focused solutions: We develop solutions that maximize productivity, minimize operations costs and decision-making processes that drive ROI within your organization.

- Future-Ready Solutions: We work with you to adopt technologies that will keep your operations competitive in the present and open to adaptation in the future to support your long-term growth and innovation.

By partnering with Citrusbug Technolabs, you are working with a team that is committed to delivering actual results and to ensuring that your manufacturing company succeeds by means of technology-driven innovation.

Future of Digital Transformation in Manufacturing Beyond 2026

The future of digital manufacturing transformation is shifting to more intelligent, autonomous, and highly connected factories. Manufacturers will leverage AI, machine learning, and advanced analytics to make real-time decisions and optimize activities throughout the supply chain as technologies change.

Generative AI will most likely be critical in design, process optimisation, and predictive modelling. Firms that invest in understanding generative AI will have a competitive advantage to rapidly prototype their products, lower costs and make better products overall.

Other trends shaping the future include:

- Hyper-Automation: The integration of AI, robots, and intelligent software to automate production and minimize manual intervention.

- Sustainability and Green Manufacturing: Digital tools will be used to trace emissions, optimize energy usage, and meet environmental compliance-related objectives.

- Advanced Analytics and Machine Learning: Insights derived from artificial intelligence will make maintenance and inventory management smarter and improve performance.

Manufacturers that adopt these innovations will be at the forefront in terms of agility, efficiency and customer satisfaction. To remain competitive with the digital transformation in manufacturing industry, adopting AI-powered solutions, flexible software systems, and data-driven approaches that can future-proof operations is the way forward.

Conclusion

Digital manufacturing is no longer optional. The shift to smart factories, artificial intelligence-based insights, predictive maintenance, and connected supply chains can make manufacturers in 2026 and beyond more efficient, agile, and competitive.

As an expert manufacturing software development agency, Citrusbug Technolabs assists companies in implementing the initiatives successfully. With strategic leadership and sophisticated technology, manufacturers can innovate, streamline their activities, and realize long-term growth.

SaaS Development

SaaS Development Web Application Development

Web Application Development Mobile Application Development

Mobile Application Development Custom Software Development

Custom Software Development Cloud Development

Cloud Development DevOps Development

DevOps Development MVP Development

MVP Development Digital Product Development

Digital Product Development Hire Chatbot Developers

Hire Chatbot Developers Hire Python Developers

Hire Python Developers Hire Django Developers

Hire Django Developers Hire ReactJS Developers

Hire ReactJS Developers Hire AngularJS Developers

Hire AngularJS Developers Hire VueJS Developers

Hire VueJS Developers Hire Full Stack Developers

Hire Full Stack Developers Hire Back End Developers

Hire Back End Developers Hire Front End Developers

Hire Front End Developers AI Healthcare Software Development & Consulting

AI Healthcare Software Development & Consulting Healthcare App Development

Healthcare App Development EHR Software Development

EHR Software Development Healthcare AI Chatbot Development

Healthcare AI Chatbot Development Telemedicine App Development Company

Telemedicine App Development Company Medical Billing Software Development

Medical Billing Software Development Fitness App Development

Fitness App Development RPM Software Development

RPM Software Development Medicine Delivery App Development

Medicine Delivery App Development Medical Device Software Development

Medical Device Software Development Patient Engagement Software Solutions

Patient Engagement Software Solutions Mental Health App Development

Mental Health App Development Healthcare IT Consulting

Healthcare IT Consulting Healthcare CRM Software Development

Healthcare CRM Software Development Healthcare IT Managed Services

Healthcare IT Managed Services Healthcare Software Testing services

Healthcare Software Testing services Medical Practice Management Software

Medical Practice Management Software Outsourcing Healthcare IT Services

Outsourcing Healthcare IT Services IoT Solutions for Healthcare

IoT Solutions for Healthcare Medical Image Analysis Software Development Services

Medical Image Analysis Software Development Services Lending Software Development Services

Lending Software Development Services Payment Gateway Software Development

Payment Gateway Software Development Accounting Software Development

Accounting Software Development AI-Driven Banking App Development

AI-Driven Banking App Development Insurance Software Development

Insurance Software Development Finance Software Development

Finance Software Development Loan Management Software Development

Loan Management Software Development Decentralized Finance Development Services

Decentralized Finance Development Services eWallet App Development

eWallet App Development Payment App Development

Payment App Development Money Transfer App Development

Money Transfer App Development Mortgage Software Development

Mortgage Software Development Insurance Fraud Detection Software Development

Insurance Fraud Detection Software Development Wealth Management Software Development

Wealth Management Software Development Cryptocurrency Exchange Platform Development

Cryptocurrency Exchange Platform Development Neobank App Development

Neobank App Development Stock Trading App Development

Stock Trading App Development AML software Development

AML software Development Web3 Wallet Development

Web3 Wallet Development Robo-Advisor App Development

Robo-Advisor App Development Supply Chain Management Software Development

Supply Chain Management Software Development Fleet Management Software Development

Fleet Management Software Development Warehouse Management Software Development

Warehouse Management Software Development LMS Development

LMS Development Education App Development

Education App Development Inventory Management Software Development

Inventory Management Software Development Property Management Software Development

Property Management Software Development Real Estate CRM Software Development

Real Estate CRM Software Development Real Estate Document Management Software

Real Estate Document Management Software Construction App Development

Construction App Development Construction ERP Software Development

Construction ERP Software Development