Utilizing AI for Efficient Inventory Management Systems

- March 19, 2025

-

2985 Views

- by Ishan Vyas

Inventory management has become a challenging puzzle in today’s fast-paced commercial environment. It has grown more difficult for businesses to track inventories and maintain an accurate “available-to-promise” status in real time as they reach a wider audience. A smooth inventory management strategy is a top priority for retailers in the present competitive environment, particularly given the increasing significance of omnichannel fulfilment. Every component of the inventory puzzle needs to fit precisely in this high-stakes game of balancing supply and demand while controlling prices.

AI is a powerful inventory management tool that allows companies to effectively monitor and control their stock. AI solves the complex problems of inventory management and streamlines the entire procedure by leveraging real-time AI algorithms and data analytics. This change is essential to changing how companies handle and resolve inventory control-related problems.

This revolutionary technology reduces operating costs and stockout risk by ensuring efficient use of resources. Because it increases decision-making precision, a well-managed inventory management system offers businesses a competitive edge in the marketplace. Businesses hoping to thrive in the modern business environment must use AI for inventory management.

How AI is Revolutionizing Inventory Management

AI is quickly becoming a key component of operational strategies in many different industries. In particular, its effect on inventory management procedures is nothing short of amazing. This is a time of significant transformation, fuelled by a growing understanding of AI’s potential to improve productivity, reduce error, and raise profitability.

The global market for AI in supply chains is expected to rise at a remarkable compound annual growth rate (CAGR) of 45.3% from 2019 to 2027, reaching $21.8 billion, according to Meticulous Research. Retail, e-commerce, and manufacturing are among the industries spearheading the adoption of AI and machine learning, with the healthcare and logistics sectors following behind.

One of the main advantages of AI for inventory management is its ability to spot patterns and trends in enormous volumes of data. AI analyses past sales performance, customer purchase trends, and shifting market dynamics to uncover insights that human review would overlook. As a result, companies can maintain optimal stock levels, predict shifts in demand, and make strategic inventory decisions.

Predictive analytics, which utilizes historical information and prevailing market conditions to assist companies in making predictions about future demand, is also dependent on AI. Companies can enhance operational efficiency and reduce shortages and excess inventory by optimizing price strategies, promoting optimization, and accelerating restocking.

The ability of AI-based inventory systems to evolve and transform over a period of time is yet another significant benefit. These systems adjust to changing business needs and market trends by continually learning and accepting real-time data feedback, ensuring that businesses remain agile and adaptable in an evolving landscape.

Key Applications of AI for Inventory Management

Inventory Forecasting

Businesses may make highly accurate predictions about their stock needs thanks to AI-driven inventory forecasting. AI assists businesses in anticipating shifts in demand and avoiding stock outs or overstocking by evaluating past sales data, seasonal patterns, and market volatility. By ensuring ideal inventory levels, this data-driven strategy lowers holding costs and boosts supply chain effectiveness.

Demand Prediction

AI-based demand forecasting uses machine learning models to study customer trends, sales history, and external market influences. By predicting future demand, companies can make procurement, production, and distribution decisions with confidence. This ability to predict reduces waste, improves resource utilization, and makes products available when and where they are required.

Inventory Segmentation

AI helps businesses categorize inventory based on demand frequency, value, and turnover rate. By segmenting inventory into high-priority, seasonal, or slow-moving categories, companies can implement targeted restocking strategies. This approach optimizes warehouse space, improves stock visibility, and ensures better inventory management tailored to business needs.

Smart Stock Management and Delivery

AI-based stock management systems monitor inventory in real time and automate the replenishment of products based on signals of demand. AI also optimizes delivery logistics through better route planning and shorter lead times. By incorporating AI into supply chain operations, companies can enhance order accuracy, lower costs, and improve process fulfilment.

Reordering

AI generates purchase orders and replenishment requests automatically. AI uses demand estimates and preset inventory policies to dynamically modify order quantities and reorder points. This expedites the ordering procedure and guarantees prompt inventory replenishment to effectively satisfy client demand. Businesses can increase overall operating efficiency by optimising inventory levels and minimising stockouts thanks to AI’s adaptable capabilities.

Warehouse Automation and Robotics

Robotics and automation technologies powered by AI revolutionize warehouse operations by enhancing efficiency and accuracy. Automated processes sort, pick, and pack with minimal human interaction, minimizing labor costs and mistakes. Robotics powered by AI also streamline warehouse layout and storage to facilitate quicker order processing and smooth inventory movement.

Dynamic pricing

Businesses can use AI-driven dynamic pricing to instantly adjust rates in response to changes in demand, rival pricing tactics, and inventory levels. Through price optimisation that appropriately reflects market realities, this proactive strategy enables businesses to maximise income. Furthermore, by carefully modifying prices to increase demand for slower-moving inventory, dynamic pricing lowers the risk of unsold items and boosts overall profitability while minimising stock clearing.

Localization strategies

Businesses can use artificial intelligence to examine demand trends and geographical preferences to customise marketing efforts, pricing schemes, and inventory assortments for particular geographic markets. AI helps firms to efficiently address local demand by recognising the distinct interests and behaviours of customers in various locations. In a variety of marketplaces, this focused strategy boosts sales performance, increases customer satisfaction, and fortifies brand loyalty. Using a top software localization platform further enhances this approach by ensuring that content, interfaces, and user experiences are tailored to each market’s language and cultural nuances, making AI-driven strategies even more effective. Furthermore, strategic choices about pricing, promotional efforts, and inventory allocation are informed by AI-driven data, which maximise overall company performance and competitiveness in local markets.

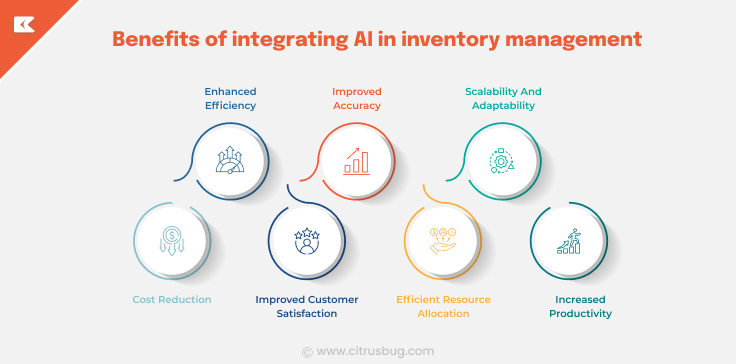

Benefits of integrating AI in inventory management

There are numerous advantages to using AI in inventory management, which not only improve operational efficiency but also affect a company’s financial performance. Let’s take a closer look at these.

Cost reduction

The potential for large cost savings is one of the most compelling reasons for companies to use AI for inventory management.

AI-driven inventory optimization makes sure companies have the proper amount of goods on hand, which reduces holding costs. Stockouts and overstocking are expensive issues that AI can help with.

Businesses can increase profitability, lower storage costs, and more efficiently distribute resources when inventory levels are optimised. This process can be further streamlined by pairing AI with procurement process management software, enabling smarter purchasing decisions and better cost control.

Enhanced efficiency

By automating repetitive operations like data entry, analysis, and decision-making, artificial intelligence improves inventory management procedures. Businesses can more effectively manage resources by doing away with physical labour, giving staff members more time to concentrate on higher-value tasks like customer service and strategic planning.

Improved customer satisfaction

By offering precise inventory projections and tailored product recommendations, AI helps businesses better anticipate and meet customer demand. Businesses may improve customer happiness and loyalty by guaranteeing product availability and providing quicker order fulfilment.

Improved accuracy

When applied appropriately, AI solutions are incredibly accurate and dependable, which lowers the possibility of error in inventory management. Precise product tracking, fewer data input mistakes, and less differences between recorded and real inventory are all results of this accuracy.

Efficient resource allocation

Insights derived from AI aid in more informed decision-making about resource utilization for inventory management. Analyzing trends, patterns, and market influences helps companies utilize resources more effectively, for instance, by making inventory level adjustments, streamlining supply chain operations, and executing targeted marketing campaigns, which result in enhanced business performance and profitability.

Scalability and adaptability

Inventory management solutions powered by AI can evolve with a company. As operations grow, AI can adjust to new goods and shifting market trends.

These systems’ adaptability guarantees their continued relevance and efficacy, regardless of how big or little a company is.

The difficulties and factors to be taken into account when using AI to inventory management will then be discussed, guaranteeing a thorough comprehension of the requirements and implications of the technology.

Increased productivity

Inventory management solutions with AI capabilities increase efficiency by automating tedious processes and provide useful insights. AI frees up staff members to concentrate on higher-value tasks by managing repetitive tasks like demand forecasts, replenishment suggestions, and inventory tracking, which promotes innovation and business expansion.

AI-Driven Inventory Optimization with Citrusbug Technolabs

For logistics and warehouse specialists, AI for inventory management is unquestionably revolutionising the industry. Businesses can attain previously unheard-of levels of accuracy, productivity, and cost savings by utilising AI. Among the revolutionary advantages AI provides are increased supply chain visibility, automatic replenishment, better warehouse efficiency, lower holding costs, and improved forecasting accuracy. Artificial intelligence’s potential in inventory management will only increase with the development of technology, providing even more chances for success and innovation.

Citrusbug Technolabs, a top developer of inventory management system software, provides logistics and supply chain companies with cutting-edge AI development services for inventory and profit optimization. With vast continuous simulative capabilities and real-time monitoring for a wide range of factors, we create custom AI software that streamlines daily operations and shields companies against unanticipated disruptions.

SaaS Development

SaaS Development Web Application Development

Web Application Development Mobile Application Development

Mobile Application Development Custom Software Development

Custom Software Development Cloud Development

Cloud Development DevOps Development

DevOps Development MVP Development

MVP Development Digital Product Development

Digital Product Development Hire Chatbot Developers

Hire Chatbot Developers Hire Python Developers

Hire Python Developers Hire Django Developers

Hire Django Developers Hire ReactJS Developers

Hire ReactJS Developers Hire AngularJS Developers

Hire AngularJS Developers Hire VueJS Developers

Hire VueJS Developers Hire Full Stack Developers

Hire Full Stack Developers Hire Back End Developers

Hire Back End Developers Hire Front End Developers

Hire Front End Developers AI Healthcare Software Development & Consulting

AI Healthcare Software Development & Consulting Healthcare App Development

Healthcare App Development EHR Software Development

EHR Software Development Healthcare AI Chatbot Development

Healthcare AI Chatbot Development Telemedicine App Development Company

Telemedicine App Development Company Medical Billing Software Development

Medical Billing Software Development Fitness App Development

Fitness App Development RPM Software Development

RPM Software Development Medicine Delivery App Development

Medicine Delivery App Development Medical Device Software Development

Medical Device Software Development Patient Engagement Software Solutions

Patient Engagement Software Solutions Mental Health App Development

Mental Health App Development Healthcare IT Consulting

Healthcare IT Consulting Healthcare CRM Software Development

Healthcare CRM Software Development Healthcare IT Managed Services

Healthcare IT Managed Services Healthcare Software Testing services

Healthcare Software Testing services Medical Practice Management Software

Medical Practice Management Software Outsourcing Healthcare IT Services

Outsourcing Healthcare IT Services IoT Solutions for Healthcare

IoT Solutions for Healthcare Medical Image Analysis Software Development Services

Medical Image Analysis Software Development Services Lending Software Development Services

Lending Software Development Services Payment Gateway Software Development

Payment Gateway Software Development Accounting Software Development

Accounting Software Development AI-Driven Banking App Development

AI-Driven Banking App Development Insurance Software Development

Insurance Software Development Finance Software Development

Finance Software Development Loan Management Software Development

Loan Management Software Development Decentralized Finance Development Services

Decentralized Finance Development Services eWallet App Development

eWallet App Development Payment App Development

Payment App Development Money Transfer App Development

Money Transfer App Development Mortgage Software Development

Mortgage Software Development Insurance Fraud Detection Software Development

Insurance Fraud Detection Software Development Wealth Management Software Development

Wealth Management Software Development Cryptocurrency Exchange Platform Development

Cryptocurrency Exchange Platform Development Neobank App Development

Neobank App Development Stock Trading App Development

Stock Trading App Development AML software Development

AML software Development Web3 Wallet Development

Web3 Wallet Development Robo-Advisor App Development

Robo-Advisor App Development Supply Chain Management Software Development

Supply Chain Management Software Development Fleet Management Software Development

Fleet Management Software Development Warehouse Management Software Development

Warehouse Management Software Development LMS Development

LMS Development Education App Development

Education App Development Inventory Management Software Development

Inventory Management Software Development Property Management Software Development

Property Management Software Development Real Estate CRM Software Development

Real Estate CRM Software Development Real Estate Document Management Software

Real Estate Document Management Software Construction App Development

Construction App Development Construction ERP Software Development

Construction ERP Software Development